Ahead-looking: A world group of scientists have printed analysis on a novel technique to develop 2D supplies utilizing a way that would carry 2D transistor-based electronics to market sooner somewhat than later.

Moore’s regulation is not lifeless simply but, and it may quickly get a brand new lease on life because of groundbreaking analysis by a world and multi-institutional group of scientists. In search of new strategies to develop 2D supplies, the researchers have seemingly developed a “promising” rising course of that would energy next-generation electronics.

Intel and different expertise corporations are onerous at work to fabricate the primary chip containing a trillion transistors, and they’re all new single atom-thick (ie “2D”) supplies and compounds as a attainable different to silicon for the manufacturing of stated transistors.

Led by Sang-Hoon Bae, assistant professor of mechanical engineering & supplies science on the McKelvey College of Engineering at Washington College in St. Louis, and different two researchers, the brand new work includes two technical breakthroughs that may make digital gadgets “quicker and use much less energy.”

The analysis has been published in Nature, and it conceives a rising methodology that may “overcome three extraordinarily troublesome challenges to create the brand new supplies.” These challenges embody securing single crystallinity at wafer-scale, stopping irregular thickness throughout progress at wafer-scale, vertical heterostructures at wafer-scale.

Whereas 3D supplies used to fabricate conventional transistors undergo a technique of roughening and smoothing to develop into an even-surfaced materials, the researchers say, 2D supplies can not and thus the ultimate result’s an uneven floor that “makes it troublesome to have a large-scale, high-quality, uniform 2D materials.”

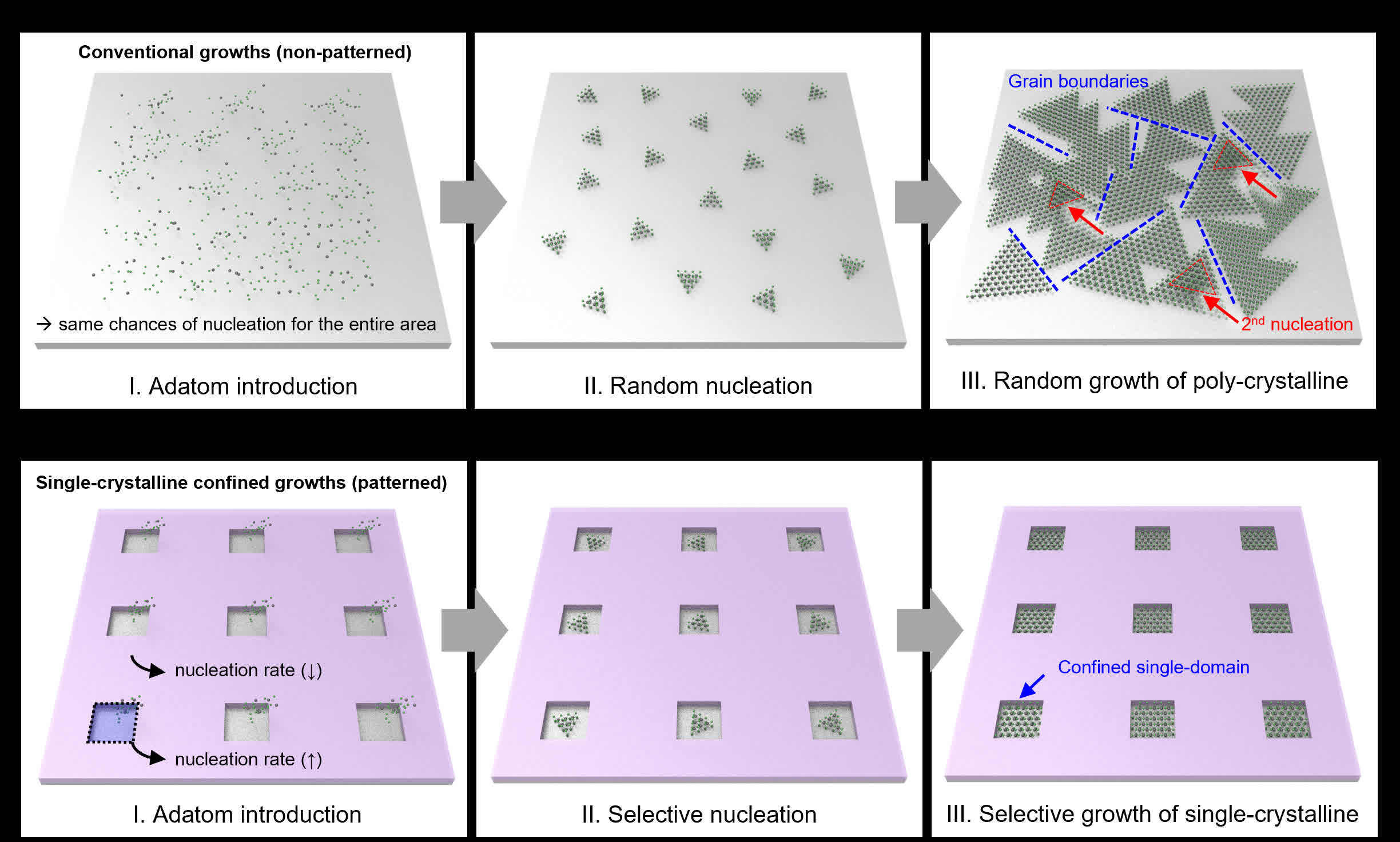

By designing a novel “geometric-confined construction that facilitates kinetic management of 2D supplies,” the scientists had been seemingly in a position to clear up the “all grand challenges in high-quality 2D materials progress.” One other technical breakthrough is the demonstration of a “single-domain heterojunction TMDs on the wafer scale.” The researchers used varied substrates and chemical compounds to restrict the expansion of the nuclei, utilizing stated substrates as a bodily barrier that “prevented lateral-epitaxy formation and compelled vertical progress.”

Based on Sang-Hoon Bae, the brand new confined progress method “can carry all the good findings in physics of 2D supplies to the extent of commercialization by permitting the development of single area layer-by-layer heterojunctions on the wafer-scale.”

The brand new achievement will lay a robust basis for 2D supplies to suit into industrial settings, accelerating the creation of latest manufacturing processes for 2D transistors. Bae stated different researchers are already finding out this new materials at very small sizes of tens to a whole lot of micrometers.

Source link