A automobile alternator will usually cost a battery at 14 volts whereas the engine is working. One ingenious maker had an epiphany: the identical expertise is likely to be tailored to do much more when related to working water. John from FarmCraft101 needed to strive his hand at repurposing a traditional automobile alternator. He disassembled the stator and manually rewound every coil to spice up the output to 200 volts, or extra if doable. Consequently, the expertise now powers a chunk of his office from a pond a whole lot of toes away, slicing line losses that might in any other case kill an ordinary 12-volt system.

Most traditional alternators have three-phase AC inside them, however earlier than it’s transformed to DC, a rectifier contained in the alternator is utilized, and a regulator maintains the voltage at a managed degree, roughly 14 volts. We’re left with a naked three-phase generator with all different elements eliminated. The rotor stays as an electromagnet with all elements powered by a small DC provide. When the rotation begins, a present flows by the stator windings. In most alternators, thick wire with a small variety of turns per coil is utilized to create numerous present with low voltage, however John has chosen to make use of the alternative.

LEGO Technic 1966 Ford GT40 MKII Race Car Building Set for Adults – Collectible Toy W/Realistic Functions…

- BUILD A RACING LEGEND – Relive motorsport historical past with the LEGO Technic 1966 Ford GT40 MKII Race Automotive mannequin package for adults ages 18 years outdated and up

- REALISTIC FEATURES & FUNCTIONS – Steer utilizing the knob on prime, open the doorways to discover the inside, elevate the engine cowl to disclose the V8 engine,…

- AUTHENTIC 1966 DESIGN – This classic race automobile mannequin options iconic black and silver design impressed by the actual Ford GT40 MKII champion automobile

He began with an affordable GM CS130 alternator, which he purchased on-line for pennies. The disassembly was easy, however as soon as he received to the stator, all the things fell aside. The unique windings have been caught in a thick layer of varnish and epoxy, and he put the stator in a toaster oven and used a paint remover to take away the unique coils. After that, it was only a matter of prying and slicing them out, which took hours.

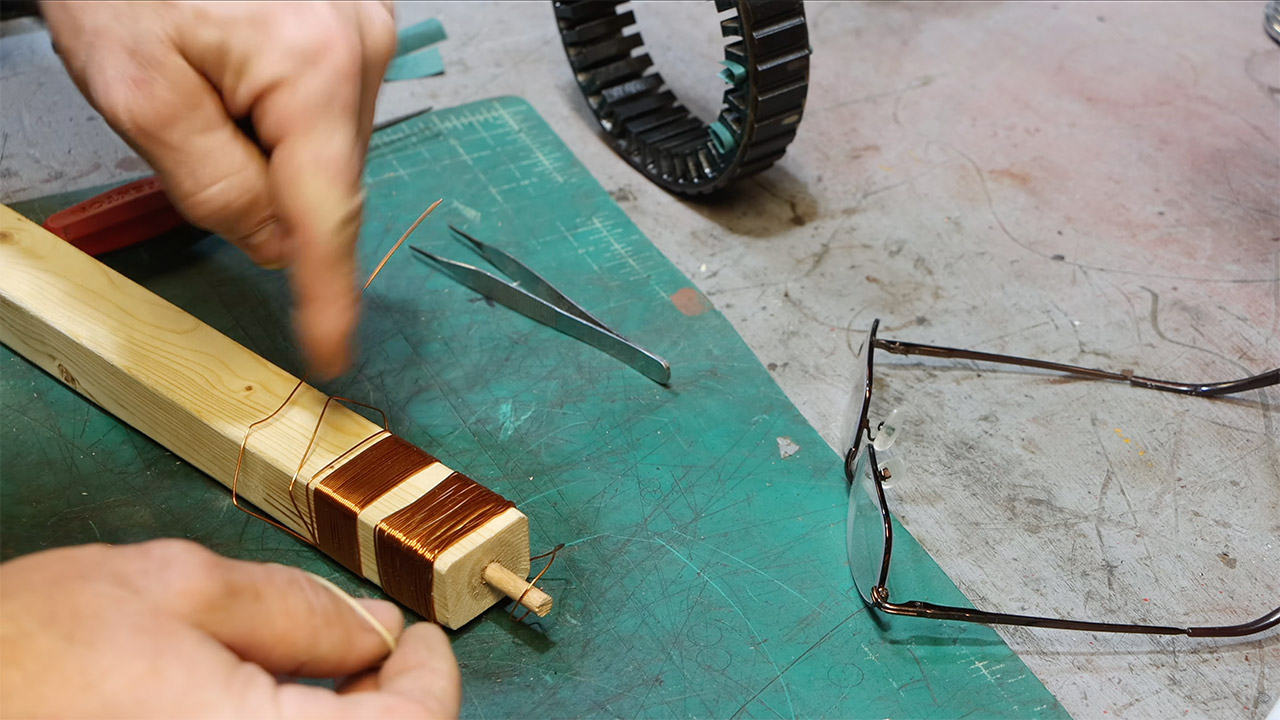

The clear slots have been then coated utilizing Nomex paper strips to behave as insulators. John then made new coils for every section utilizing picket kinds and 22-gauge copper wire coated with enamel. The brand new coils had 30 turns every, in contrast to the unique coils, which had a relentless 4 or 8 turns per coil. He made 12 coils per section, and every section had 36 slots. Moreover, he made the phases 120 levels aside to make sure an entire steadiness within the three-phase present. To do that, he alternated the path of the coils, inflicting the north and south poles of the rotor to induce the required present circulate.

As soon as all of the coils have been put in contained in the stator, he made certain to house them out in layers, held securely in place with small 3D printed PETG items that merely snap over the holes. As soon as all three phases have been stuffed in, he related them up in a star (wye) configuration to extend the line-to-line voltage output fairly than making an attempt to extend the present output to its fullest extent with a delta configuration. The studying of three ohms per section confirmed that the decrease gauge wire he had chosen would certainly sacrifice a bit present for lots extra voltage.

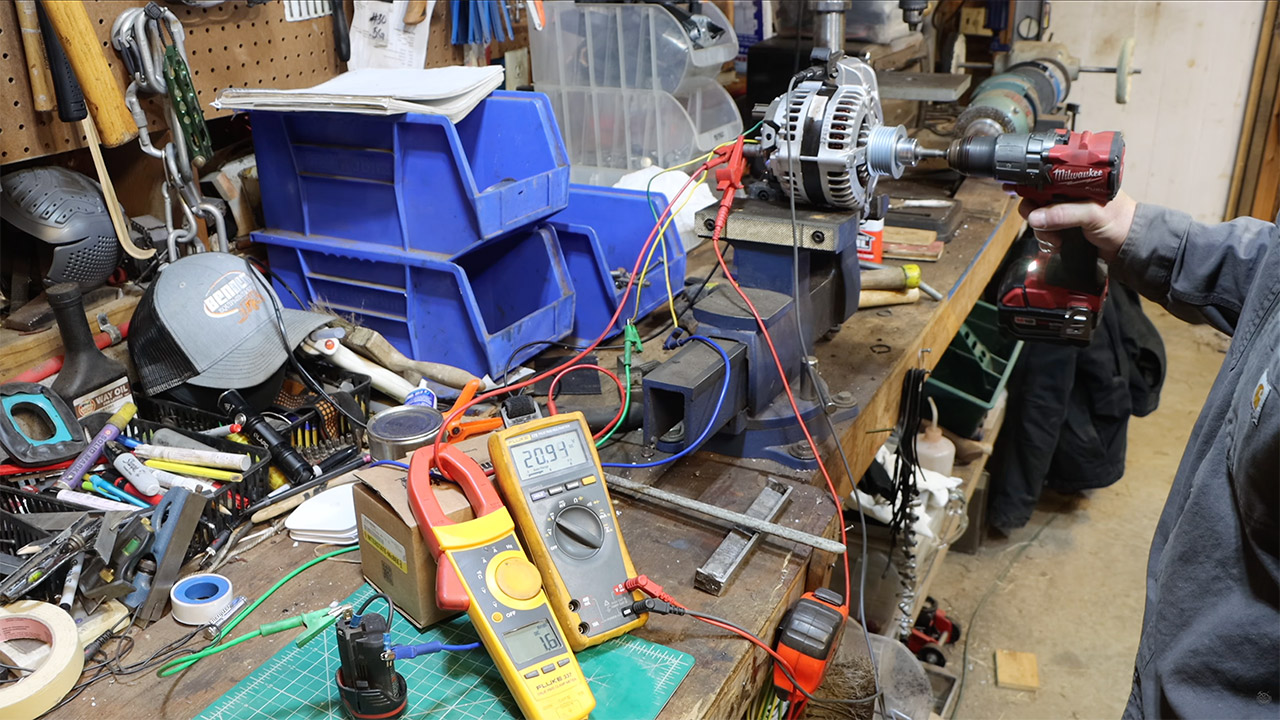

Reassembly restored the rotor brushes, no less than in the intervening time, however he uncared for the inner diodes and regulator, aspiring to compensate by using an exterior bridge rectifier to transform the three-phase AC to DC. Bench experiments have been performed with an outdated drill and, later, a geared grinder to spin the shaft on top of things. When the drill received the shaft as much as round 1500 RPM, the voltage was round 100 volts with the multimeter set to open circuit mode. Then, as he cranked it as much as round 290 volts with the grinder, it turned evident that it had numerous potential. Including a load of resistors to duplicate real-world use, the machine produced an astonishing 700 watts. In fact, the voltage sagged slightly below load, however even unloaded, it produced considerably extra energy than a typical alternator.

John hopes to get roughly 240 volts out of this contraption, which ought to be sufficient to energy his hydro utility so long as the pond turbine spins the alternator at an affordable fee by way of the belts. He’ll positively have to carry out some pulley sizing to convey it as much as a pleasant secure 3000 RPM for optimum energy. Sure, extra voltage implies decrease present in the long term to the store, so he can use thinner, cheaper wire and nonetheless transport the identical energy with out losing it on losses or sagging too far within the first place. He finally intends to switch the magnetic rotor with neodymium everlasting magnets, which can get rid of the necessity for brushes, excitation energy, and different pointless complexity.

[Source]

Source link