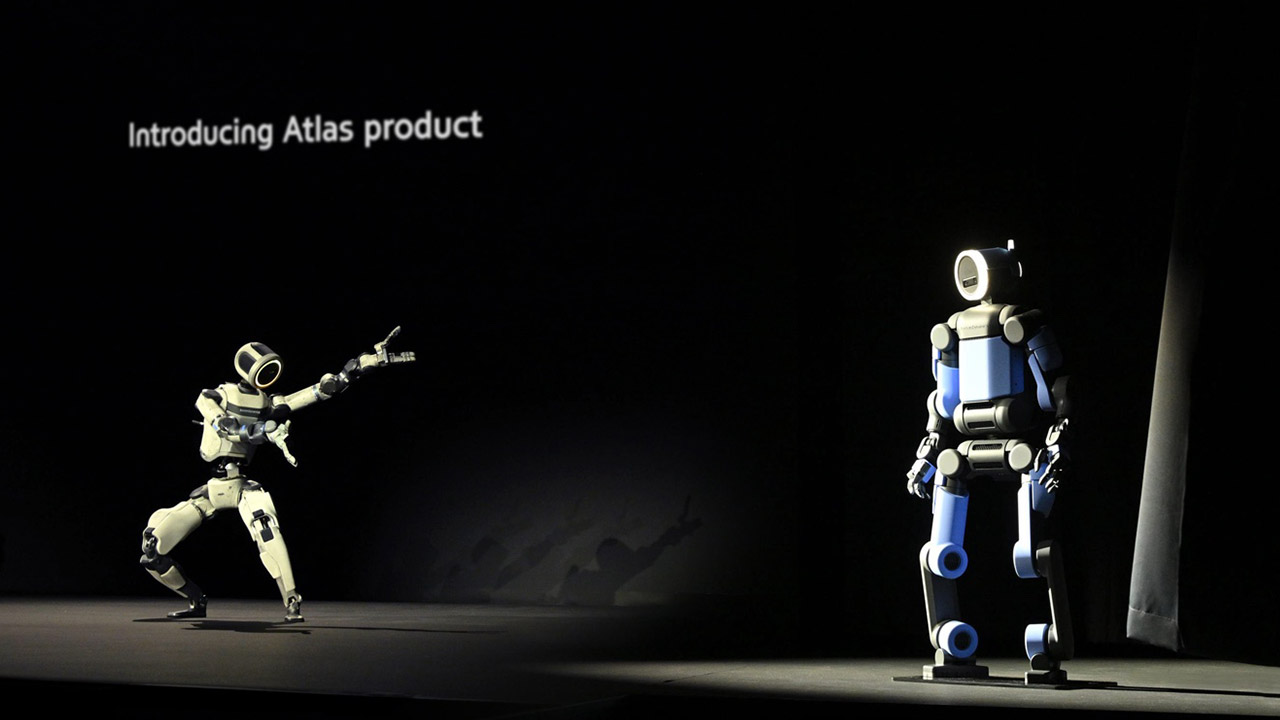

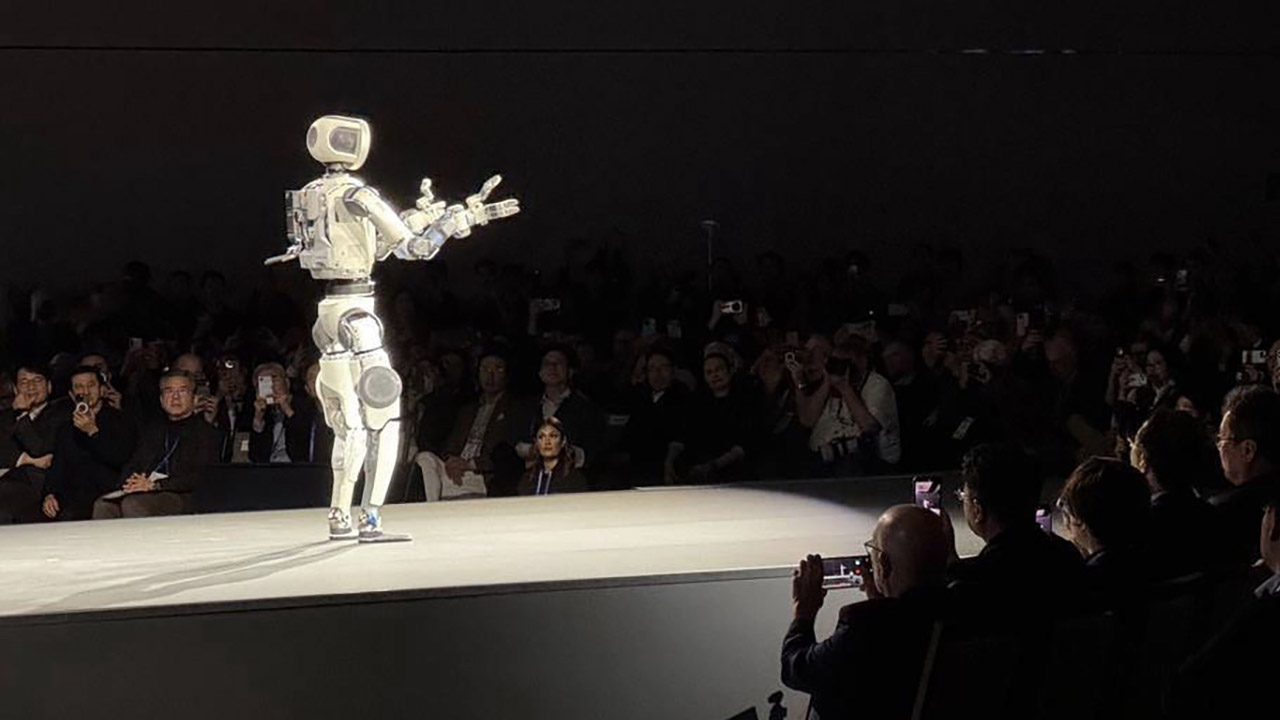

Hyundai Motor Group made a shock announcement at CES 2026 in Las Vegas, disclosing plans to have Boston Dynamics-built robots do essential work in vehicle manufacturing. Executives laid forth a method for spreading humanoid robotics throughout manufacturing traces, starting small and increase massive.

On the heart of all of it is Boston Dynamics’ brand-new Atlas robotic, a very electrical humanoid that not too long ago emerged from Boston Dynamics’ lab. Atlas was constructed by a group of engineers who gave it 56 joints, nearly all of which might spin round in a full circle, and arms geared up with contact sensors to assist it acquire a agency grip on objects. The machine can raise massive issues weighing as much as 110 kilos, attain heights of as much as 7.5 ft, and, surprisingly, can resist temperatures starting from freezing chilly to burning scorching, all whereas enduring the occasional water splash.

Unitree G1 Humanoid Robot(No Secondary Development)

- Top, width and thickness (standing): 1270x450x200mm Top, width and thickness (folded): 690x450x300mm Weight with battery: approx. 35kg

- Whole freedom (joint motor): 23 Freedom of 1 leg: 6 Waist Freedom: 1 Freedom of 1 arm: 5

- Most knee torque: 90N.m Most arm load: 2kg Calf + thigh size: 0.6m Arm arm span: approx. 0.45m Further massive joint motion area Lumbar Z-axis…

Manufacturing of the industrial Atlas mannequin started on the identical day at Boston Dynamics’ headquarters in Boston, and all items scheduled to ship in 2026 have already been assigned to Hyundai vegetation and accomplice websites. Hyundai is taking a cautious strategy, evaluating the robots on a process-by-process foundation to make sure their reliability earlier than assigning them additional obligations.

The total-on deployment will start in 2028 at Hyundai’s Metaplant America in Savannah, Georgia, the place the Ioniq 5 and Ioniq 9 are assembled. The early Atlas items are assigned comparatively easy duties, like as transporting components to explicit spots on the manufacturing line as wanted. People can be readily available to regulate issues and be certain that the robots are functioning correctly, and instructing them a brand new exercise usually takes solely a day or two. By 2030, these machines are predicted to be able to doing extra subtle duties similar to element meeting.

Behind all of it is a important improve in manufacturing capability, as Hyundai is constructing a brand new robotics manufacturing unit in america, with a portion of a $26 billion capital injection over 4 years starting in 2025 going towards it. This new plant is deliberate to provide 30,000 robotic items per yr by 2028, assembly demand for tens of 1000’s of Atlas robots in any respect Hyundai amenities the world over. A devoted coaching heart, the Robotics Metaplant Utility Heart, which is able to debut in america in 2026, will function a testing floor for robots earlier than they’re transferred to precise manufacturing flooring.

Hyundai has some key companions on board with this one. Hyundai Mobis, an affiliate, contributes crucial actuators and elements, whereas Hyundai Glovis, a logistics arm, manages provide chains. Exterior collaborators embody NVIDIA, which supplies the mandatory simulation instruments, and Google DeepMind, which lends their expertise in subtle AI fashions to supply the robots further decision-making energy.

Different Boston Dynamics improvements have already confirmed efficient in the actual world. Spot, the four-legged robotic, is maintaining a tally of issues and gathering knowledge in over 40 nations, together with Hyundai websites, whereas Stretch, the warehouse specialist, has transported an eye-watering 20 million packing containers globally since 2023. Atlas builds on their accomplishment and takes it to an entire new stage.

Source link