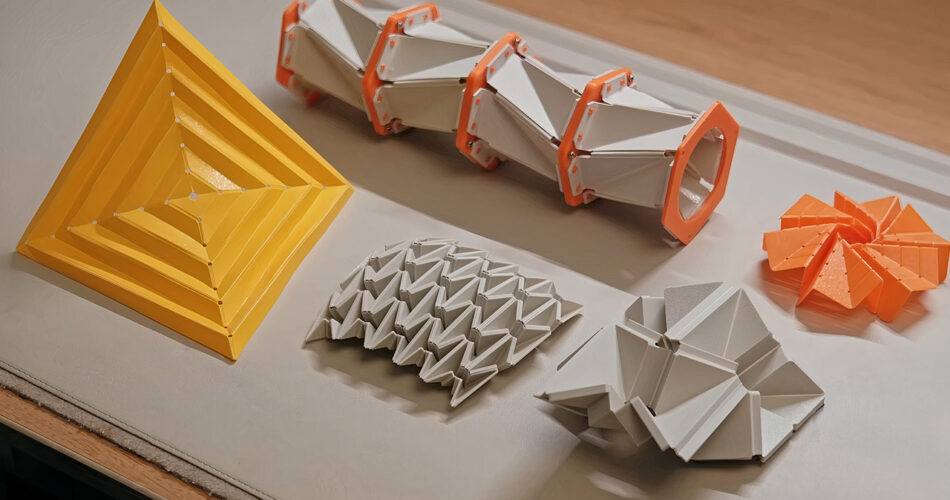

Matthew Lim, a designer with an eye fixed for the unusual, has spent loads of time determining incorporate the normal artwork of origami into the world of 3D printed objects. His most up-to-date video showcases a wide range of printed items that fold elegantly, retain their shapes, and look like stuffed with mechanical potentialities.

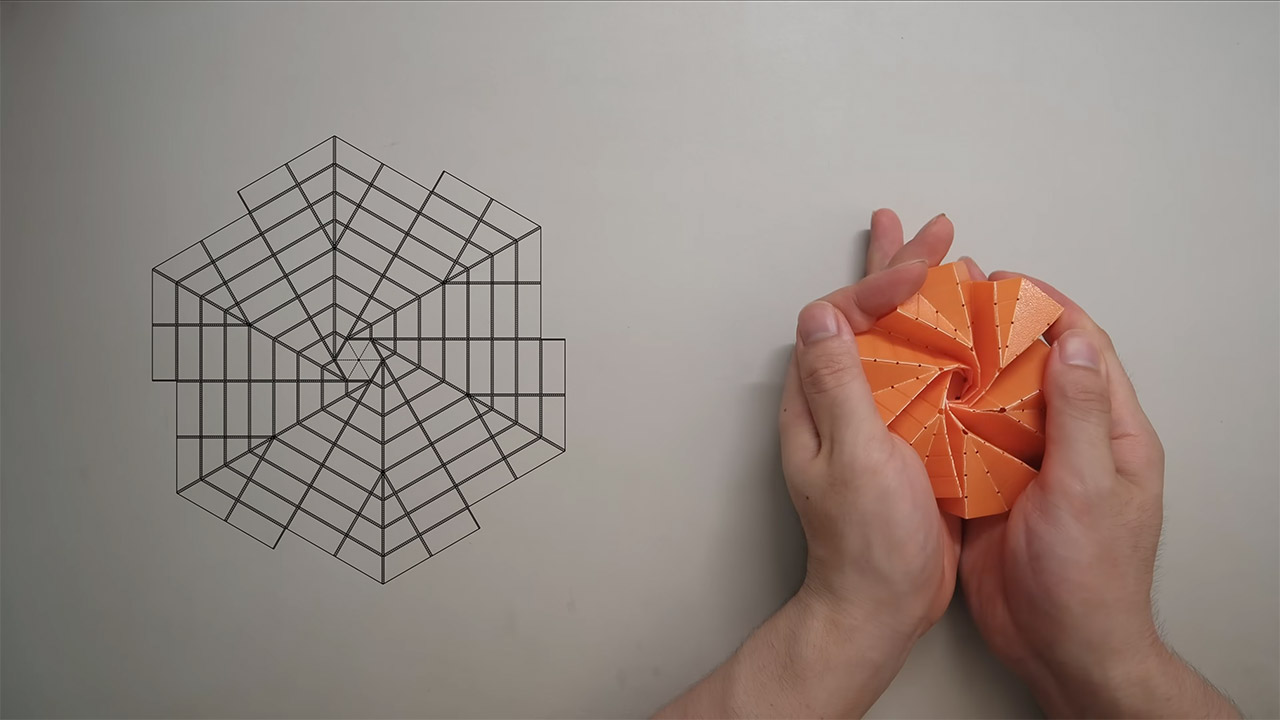

The whole lot begins with primary ideas, as a result of origami is predicated solely on these ultra-precise crease patterns: mountain folds that elevate up and valley folds that drop down. Lim develops these in his CAD software program, Fusion 360, by designing flat sheets with strong panels and skinny creases (0.2 millimeters thick) that permit the fabric to bend. He additionally makes tiny little holes on the intersections the place the folds meet, in order that when the printer lays down the fabric, it doesn’t develop into tangled up in a jumble.

Sale

Bambu Lab P1S Combo, P1S 3D Printer and AMS, Support Up to 16 Colors/Multi Materials, 500mm/s Fast…

- As much as 16 Colours: Carry your designs to life with vibrant multi-color/multi-material printing capabilities, excellent for showcasing your creativity….

- 500mm/s and 20000 mm/s² Acceleration True Excessive Velocity: Do not wait round to your masterpieces. Lightning-fast printing velocity allows you to give attention to…

- Enclosed Design: Totally enclosed physique improves print efficiency for superior filaments. Automated Mattress Leveling: Say good day to high-quality, profitable…

To get began, he begins with a easy mannequin such because the pajarita chook. First, he unfolds a paper model of the chook and maps the crease patterns, however then modifies them such that his printed plastic model is biased someway. Then he prints the whole factor. In consequence, the chook folds up into a beautiful form with hinges that may bend with out breaking. He’s in a position to take a look at the boundaries of what these printed components can accomplish as he turns into extra subtle, and he goes for some fairly insane shapes.

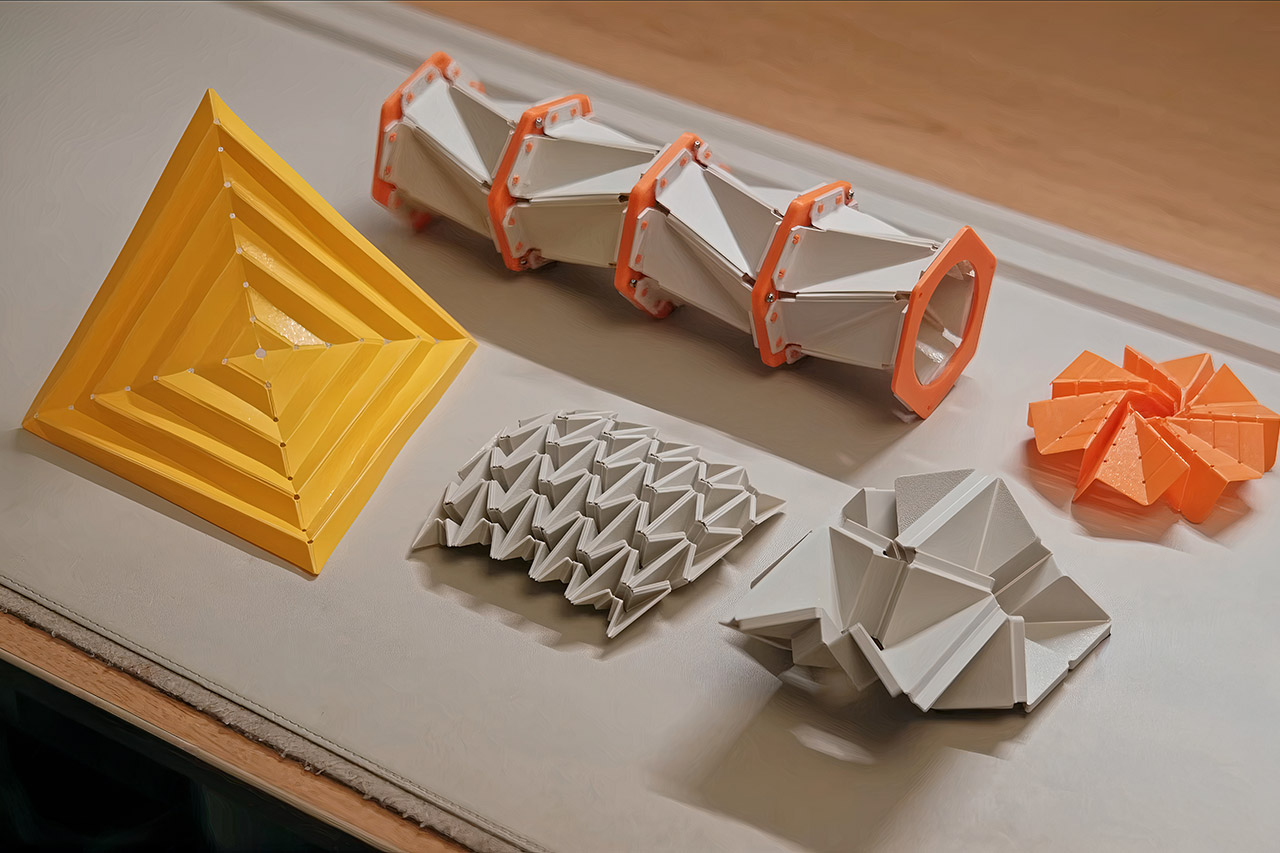

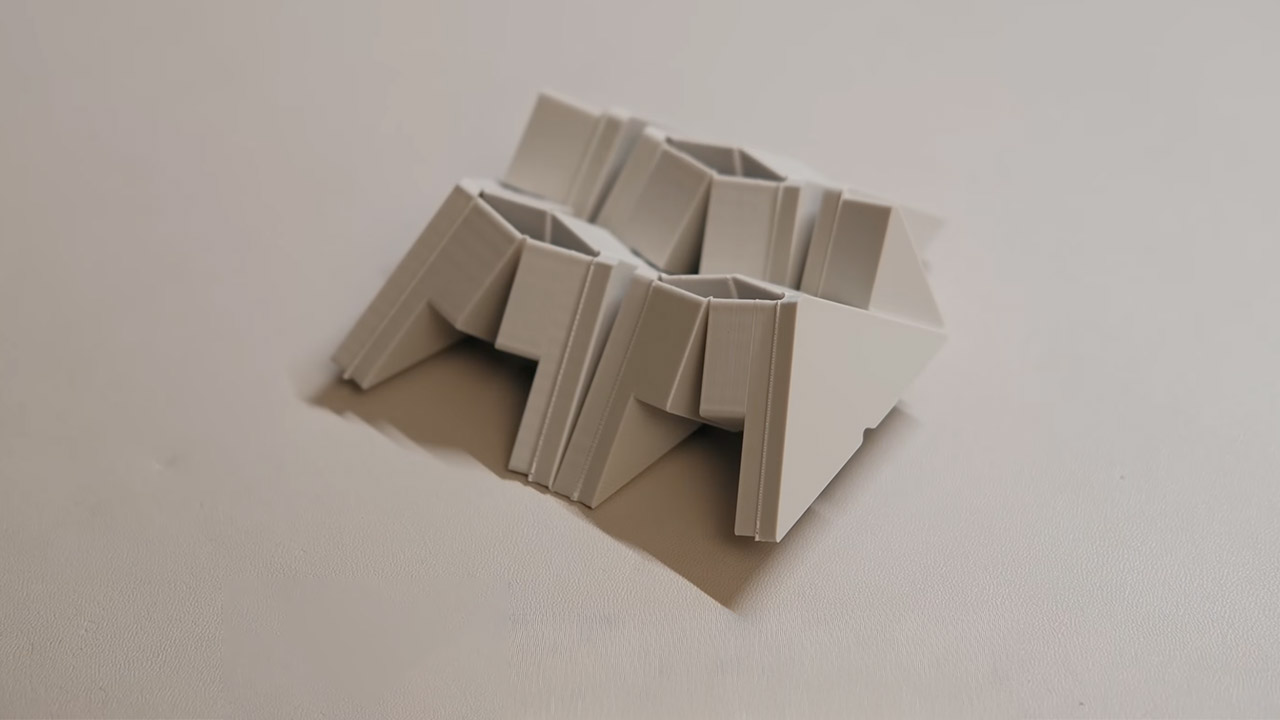

A hyperbolic paraboloid is a form that looks like a mouthful, but it surely’s basically a curved, twisted floor that’s tough to attain via some other technique of manufacture. Nevertheless, printed as a skinny sheet, you may purchase certainly one of these and skip the helps required if printed solidly. What’s even cooler is that this demonstrates how folding could make shapes that may usually require much more materials.

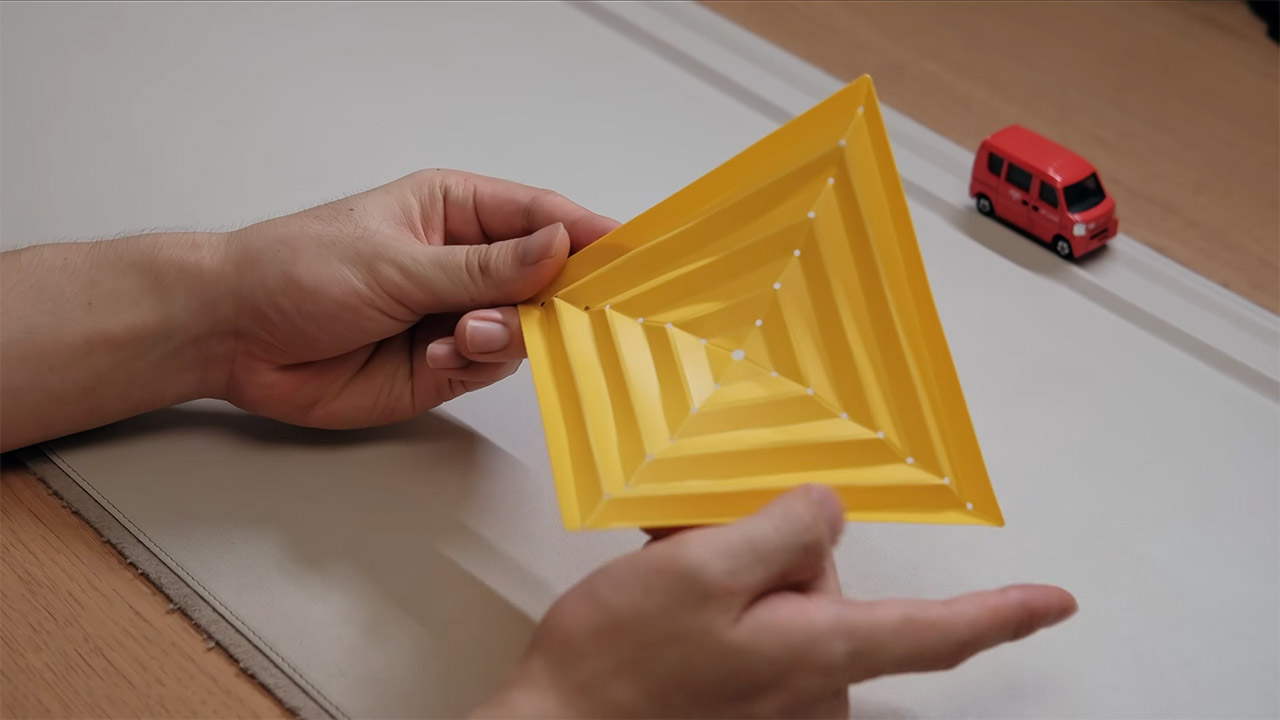

His satellite tv for pc flasher sample, which was impressed by the kind of deployable buildings seen in area missions, has these radial folds that twist spherical, and when folded up, it strikes from fully compact to completely deployed in a single twist. The movement is solely decided by geometry.

There are points, in fact, as a result of denser patterns, akin to a waterbomb tessellation, which has some unusual dancing movement because it expands, compresses, and twists, initially outcome within the hinges snapping off or the panels colliding when printed flat. Nevertheless, Lim found by way of his analysis on thick-panel origami that in the event you offset the panels alongside particular creases, shifting them over by twice the thickness of the panel, it’s possible you’ll find yourself with stronger, thicker items that fold up completely with none hurt. It seems you can scale up the design to create bigger variants.

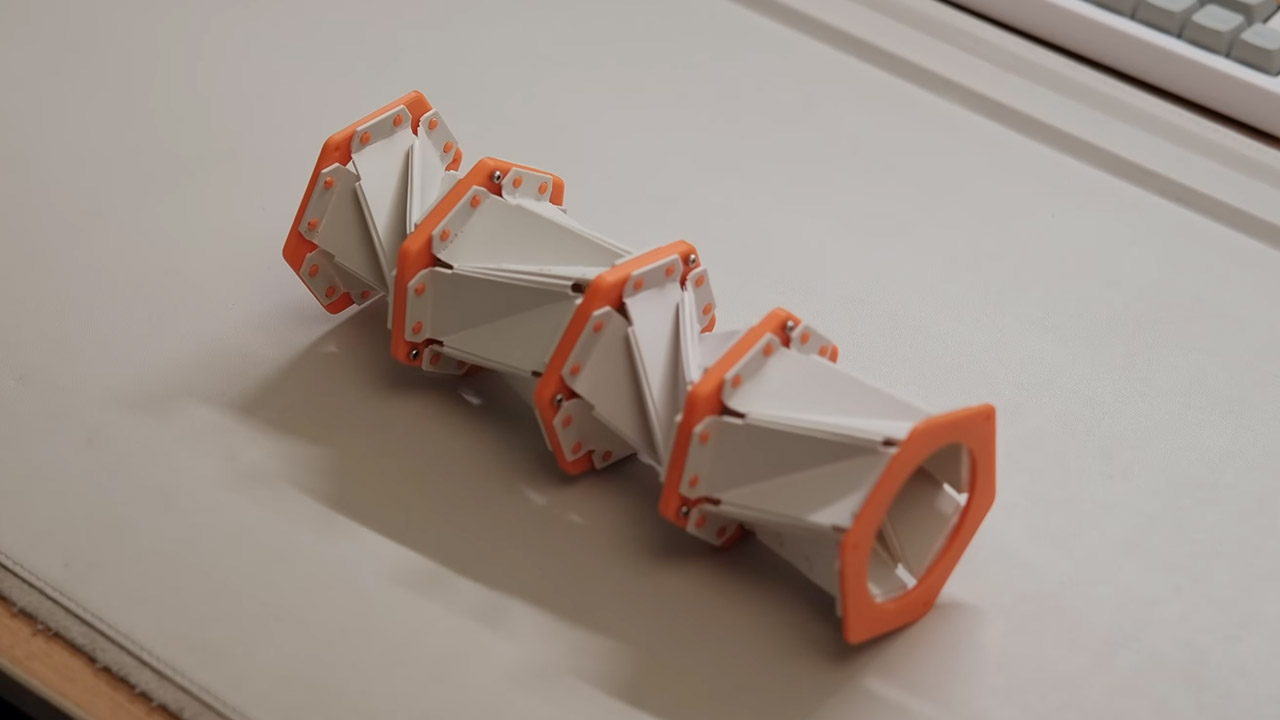

His signature piece is the Kresling spring, which was initially developed by architect Biruta Kresling. It’s a type of issues the place the parametric equations in CAD regulate the variety of models, the peak, the size, and the angle at which it twists. He produced it in PLA utilizing a Bambu Lab printer, and the spring is held along with little snap-fit pins, eliminating the necessity for glue. It snaps forwards and backwards between two steady states, or it operates like an ordinary spring when correctly configured. Once you stack the models with alternating creases, it generates a intelligent linked motion during which twisting compresses the models sequentially.

These prints exhibit how origami is all about effectivity, using the least quantity of fabric to attain most energy, which may also be utilized to 3D printing. You possibly can print out these flat designs shortly, fold them into varied sensible shapes, and incorporate mechanics akin to responsive hinges and bistable springs. Lim’s work is a wonderful instance of the chances for deployable instruments, compact buildings, and light-weight programs that may transfer with out using typical joints.

[Source]

Source link