When the time comes to begin your 3D printing journey, you’ll rapidly notice you’ve bought loads of choices in entrance of you. Along with being guided by your price range and the way a lot house you possibly can dedicate to the pastime, in some unspecified time in the future, you’ll must ask your self whether or not it’s best to go along with filament or resin.

Whereas there are nice arguments in favor of each, I’ve gone down the rabbit gap, and it’s clear that filament is the correct selection for me. Right here’s why.

What’s the distinction between resin and filament 3D printers?

Filament 3D printing, often known as FDM (fused deposition modeling) or materials extrusion, includes melting filament which is then deposited in layers to print an object. There are many different types of filament, from comparatively flimsy and low-cost PLA by means of to carbon-fiber bolstered supplies for distinctive sturdiness.

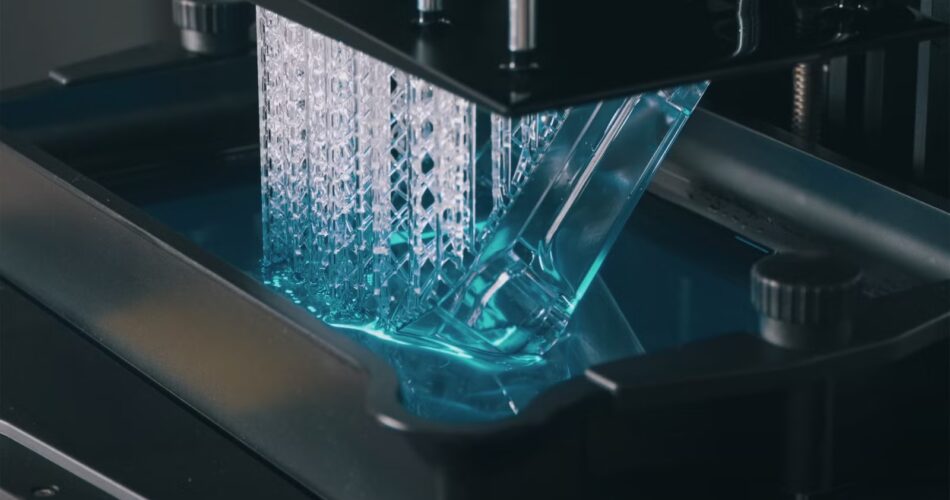

Against this, resin printers (just like the Elegoo Mars 4 DLP pictured above) work by utilizing stereolithography (SLA) or direct mild processing (DLP) to harden liquid, successfully curing a print in place. Resin printers successfully “develop” a mannequin out of a resin bathtub.

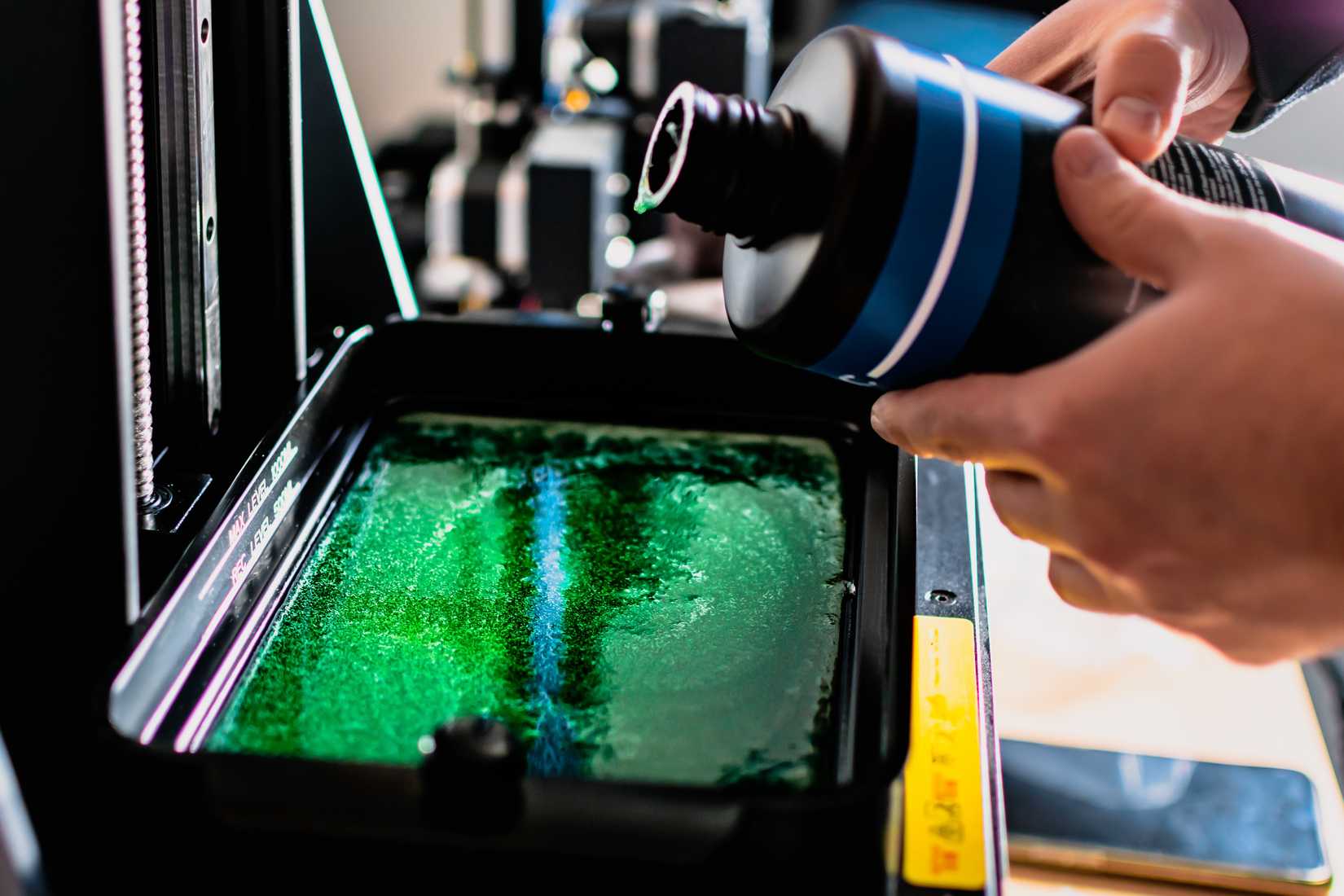

Resin may be messy and extremely poisonous

By far the largest concern for me with regard to resin printing is simply how poisonous the print materials is. Although water-washable resins have helped to mitigate a number of the dangers, the resin nonetheless must be dealt with with care in a manner that’s merely not the case when printing with non-toxic filaments like the ever-present PLA.

Along with requiring private protecting gear like nitrile gloves and ideally a respirator, resin printing requires satisfactory air flow. I’m going to be placing my printer on a desk, which implies it’s going to be sharing my dwelling house. This isn’t to say that filament printers get a free go (since some kinds of filament, like ABS, additionally require satisfactory air flow for protected use), however the dangers related to PLA are minimal because it’s primarily plant starch.

By comparability, resin carries with it the danger of publicity to dangerous chemical substances like formaldehyde. Some kinds of resin have a extra noticeable “plasticky” odor, which is perhaps disagreeable should you’re spending loads of time in shut proximity. There are additionally issues in regards to the dangerous results that these gases can have on pets, significantly birds (that are extremely vulnerable to poisoning). I’m absolutely conscious that my cats will determine {that a} good heat 3D printer is a good place to sleep.

Resin waste must be disposed of correctly, and when issues gowrong, this implies coping with a moist and sticky mess. When a filament print fails, you may find yourself with a hardened blob or spaghetti-like construction, however at the very least it’s straightforward to cope with. Failed resin prints nonetheless have to be cured earlier than they are often disposed of, and the alcohol used on this course of needs to be evaporated safely too.

Filament is nice sufficient for my use case

Some folks select to make use of resin whatever the drawbacks, and for good cause. These printers can produce extremely detailed, high-resolution prints with splendidly easy surfaces. They’re additionally quicker to print, quieter, and extremely spectacular to observe. The perfect 3D printing time-lapse movies are made with resin printers.

This makes resin printers particularly good for creating tabletop miniatures, small detailed fashions, mechanical keyboard keycaps, and jewellery. They’re generally used to quickly prototype dental implants, for instance.

By comparability, filament printing doesn’t look nearly as good. Since filament is deposited line by line, you’ll get extra seen strains within the remaining print. If you wish to maximize high quality, you’ll want to chop down on the scale of those strains, which implies rising the time it takes to provide a print. For me, that’s not an issue.

I’m seeking to create sensible objects, principally out of PLA, to be used round the home. I need to train myself the way to design fashions that may remedy issues round the home. I’m additionally not in opposition to getting a Dremmel and a few sandpaper out for the prints that I actually need to look their very best.

I’m too lazy to cope with resin’s post-print workflow

Whenever you print an object with a filament printer, it’s best to look forward to the print mattress to succeed in room temperature and for the mannequin to harden earlier than you dive in along with your grubby arms. That is often someplace round half-hour, should you don’t need to danger damaging or deforming the mannequin. Congratulations, you’re finished.

With resin, you’re simply getting began. Bear in mind once we talked in regards to the poisonous properties of resin photopolymers? You’ll want to clean off the extra resin as soon as your print has accomplished. This usually includes eradicating any extra print materials by hand, cleansing with 91% isopropyl alcohol, after which giving the print a remaining wash with soapy water.

Lastly, you’ll want to remedy the resin. You are able to do this both by leaving your fashions in daylight for round 8 hours (or much less, till the print now not feels sticky to the contact), or by utilizing a curing station that makes use of UV lights, which is often a lot quicker. Alternatively, you should purchase an all-in-one washing and curing station.

As a lot as I like the unrivaled element and smoothness of resin prints, that is extra effort than I’m prepared to place in.

Filament is cheaper and stronger

Comparisons in value won’t essentially be essentially the most helpful metric attributable to the truth that resin printers are often used to make smaller gadgets and have decrease print volumes, but it surely’s nonetheless a legitimate level of distinction between the 2 applied sciences.

Take a producer like Elegoo, which produces each filament and resin printers, for example. 1KG of essentially the most primary standard PLA prices $14, and is on the market in a spectrum of colours (together with combine and match packs). By comparability, Elegoo’s 8K standard resin prices $25 and is available in 4 colours. Water-washable resins are just a little dearer ($29), whereas powerful resin begins at $33 per KG.

By comparability, stronger filaments like Elegoo’s PETG-CF (carbon-fiber bolstered) price $19 per KG or $22 for the PLA model. These harder filaments are at all times going to be extra sturdy than the hardest resin. Resin prints merely aren’t as sturdy since they’re much more brittle, and are much less suited to outside use.

For a lot of who select resin printers, this isn’t a deal-breaker. As somebody who’s seeking to create purposeful prints from a wide range of supplies and who would really like the flexibleness to have the ability to produce gadgets that may face up to the cruel Australian solar, filament is the best way to go.

There is no such thing as a good 3D printer. Even within the filament printing world, you’ll want to steadiness your need for print quantity with house and price range constraints. Some printers are quicker, others provide higher decision, some use open-source fashions, whereas others lean right into a closed ecosystem.

The perfect you are able to do is decide the correct device for the job, primarily based in your desires and wishes. Or, should you’ve bought the cash and house to spare, purchase each!

Source link