- Ultimaker introduces Safe Line 3D printers for protection use, no Wi-Fi, no cameras

- Air-gapped fashions depend on USB workflows, eliminating cloud providers

- Tamper-resistant firmware, encrypted file dealing with, and sealed {hardware}

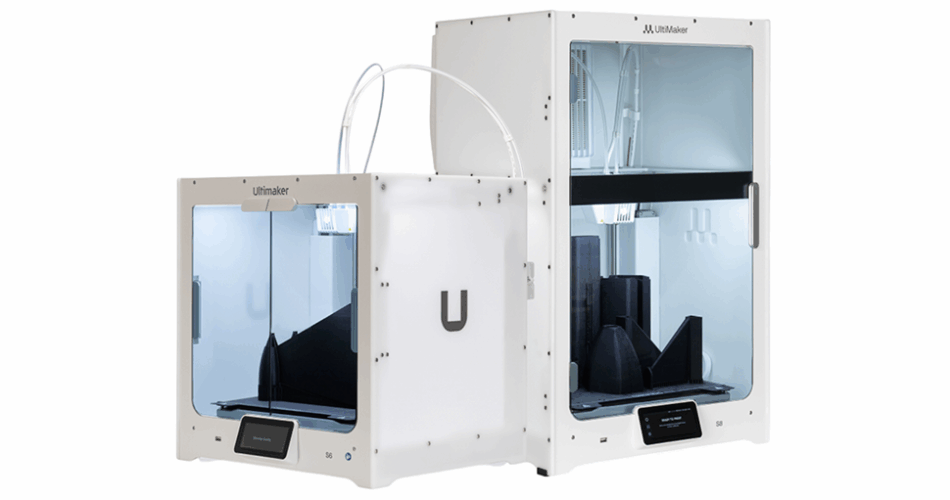

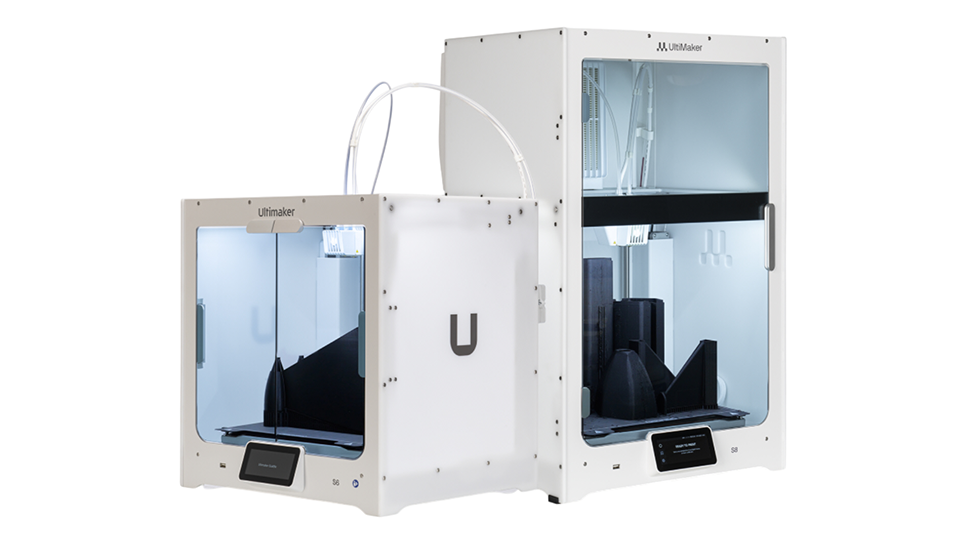

Ultimaker has introduced a brand new vary of Safe Line 3D printers designed for protection and high-security environments.

The S6 Safe and S8 Safe come with out Wi-Fi connections or exterior cameras, to be able to get rid of potential vulnerabilities.

The launch comes amid growing awareness of security risks in connected 3D printing systems. Last year, users of the Anycubic 3D printer reported receiving an unsolicited message on their gadgets warning of a “vital vulnerability” and urging them to disconnect from the web to stop potential exploitation.

Air-gapped and secure

We’ve also previously reported how watermarks embedded in 3D printed objects can unintentionally reveal non-public data, and the way destroying a 3D printed ghost gun is probably not sufficient to erase proof – forensic specialists can still recover traceable data from fragmented parts.

Towards this backdrop, Ultimaker’s Secure Line is constructed to function in environments the place information safety and system reliability are vital.

Each fashions are air-gapped, use USB-only workflows and don’t depend on cloud providers, decreasing their publicity to cyberattacks.

Andy Middleton, SVP EMEA and World Advertising and marketing at Ultimaker, stated safety was the driving issue behind the event.

“The Safe Line represents a strategic leap in making additive manufacturing a trusted and deployable asset for protection organizations. By combining industrial-grade 3D printing with uncompromising safety, the Safe Line allows the manufacturing of mission-critical parts on the level of want, safely, reliably, and with full management over their information and infrastructure,” he stated.

Security measures embody tamper-resistant firmware flashed on the manufacturing unit, encrypted and auditable file dealing with, and hardware-sealed parts.

The compact printers are primarily to be used in cellular items, bases, or naval deployments, the place they can be utilized to 3D print substitute elements or instruments immediately in operational settings.

Arjen Dirks, CTO at Ultimaker, stated, “We designed our Safe Line merchandise with safety constructed into each layer and to fulfill internationally acknowledged requirements, combining reproducibility and long-term reliability in a kind that ensures tactical functionality in protection environments.”

The S6 Safe and S8 Safe use the corporate’s Cheetah movement planner, high-flow print cores, and an up to date feeder system.

Ultimaker claims this mix gives sooner print speeds and improved high quality, though unbiased testing has not but been reported.

The safe 3D printers can be found in restricted batches to certified protection and aerospace organizations solely. There’s no official pricing, however they arrive with a two-year service plan.

You might also like

Source link