Brit chipmaker Pragmatic Semiconductor has created a 32-bit microprocessor in a “versatile know-how that’s absolutely purposeful whereas flexed.”

The Flex-RV processor is not about profitable efficiency benchmarks, however creating a brand new bending compute resolution to slot in unconventional locations. That stated, it does embody a programmable machine-learning {hardware} accelerator and RISC-V directions for utilizing it, so it could actually do some easy AI work.

Ditching conventional silicon, commonplace for standard processors and compute units, this RISC-V-based microprocessor makes use of indium gallium zinc oxide (IGZO) transistors layered on polyimide.

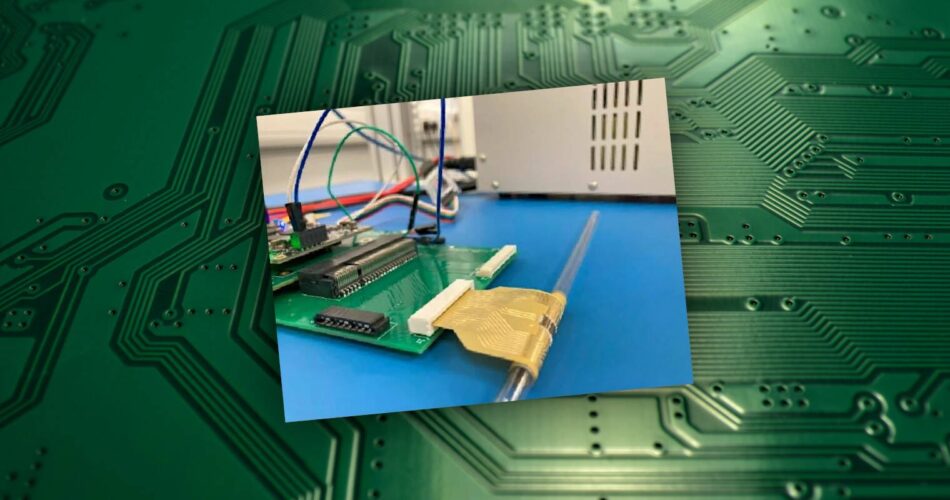

Bendability take a look at of the Flex-RV on a FlexPCB whereas executing take a look at packages – determine from the Nature paper

IGZO is extra generally present in flat screens and touchscreen units. In actual fact, the Flex-RV processor is a chip that works whereas wrapped round a pencil, whereas clocking in at a leisurely 60 kHz. However who cares about clock speeds when the purpose is reasonable and disposable tech?

The Flex-RV sports activities simply 12,600 logic gates, however that is definitely sufficient to energy a brand new era of embedded purposes – issues corresponding to good bandages, versatile electronics, and interactive packaging. The RV32E Flex-RV chip is programmable, bendable, and inexpensive. The first use case is for the on a regular basis units that silicon cannot or will not attain. Cambridge-based Pragmatic’s pitch is straightforward: Put computing the place silicon is not relevant.

The Brit firm behind the tech opened its Pragmatic Park web site at Durham, northeast England, earlier this 12 months, claiming it was the UK’s first manufacturing facility for producing 300mm semiconductor wafers.

The Cambridge boffins revealed a paper on the tech behind Flex-RV in Nature earlier this week.

This is not nearly making chips flexible only for enjoyable; the actual kicker is the low price of manufacturing. IGZO fabrication would not want the clean-room-level precision that silicon calls for, slicing all these main manufacturing overheads. Because it would not shatter below stress, the Flex-RV additionally would not want the costly packaging of silicon chips. Being low-cost, rugged, and adaptable makes it the proper match for fast-moving client items, disposable medical tech, and anyplace else you’d by no means assume to place a CPU.

The tech is bending the principles, fairly actually, and it is extra than simply technical gymnastics. It is about making computing low-cost and versatile. Common readers will know we have beforehand lined boffins’ efforts to make flexible chips and electronics – for instance, here, here, and here.

This type of silicon-free know-how marks a major shift from the power-hungry paradigms we see in silicon to being extra pervasive, albeit far slower by way of uncooked MHz (kHz in actuality).

It is also good to see extra RISC-V-compatible silicon flying round, filling the nooks and crannies the place regular silicon cannot bodily go. Do not anticipate to run Crysis in your subsequent good bandage or medical system, however we would simply be heading for a future the place each surface-level system, product, and packet has a mind powered by a Flex-RV chip/IC or an analogous silicon-free system. ®

Source link