Picture credit score: Gustavo Raskosky / Rice College

Rice College scientists have developed engineered wood that may lure carbon dioxide by means of a scalable course of that’s not solely energy-efficient, however makes the fabric even stronger than the actual factor. This feat was achieved by discovering a strategy to incorporate molecules of a carbon dioxide-trapping crystalline porous materials instantly into the wooden.

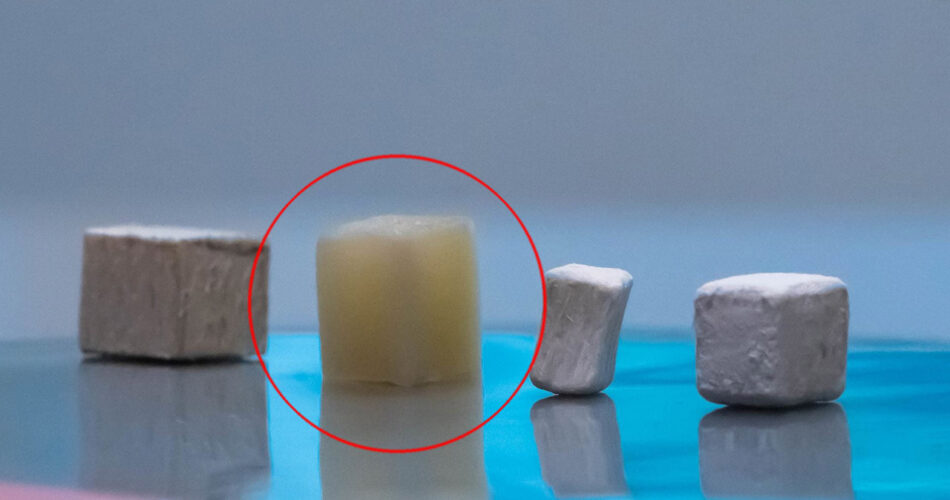

The method concerned clearing out the community of cellulose fibers that offers wooden its power by means of a course of generally known as delignification. This delignified wooden is then soaked in an answer containing microparticles of a metal-organic framework (MOF) generally known as Calgary framework 20 (CALF-20). These are high-surface-area sorbent supplies utilized for his or her capability to adsorb carbon dioxide molecules into their pores.

The manufacturing of structural supplies resembling metals or cement represents a major supply of business carbon emissions. Our course of is easier and ‘greener’ when it comes to each substances used and processing byproducts. The subsequent step could be to find out sequestration processes in addition to an in depth financial evaluation to grasp the scalability and business viability of this materials,” stated Muhammad Rahman, Supplies Scientist at Rice College.

Source link