Intel’s CEO Pat Gelsinger is an admirer of the company’s iconic leaders – Gordon Moore, Robert Noyce and Andy Grove – and has a five-year plan to bring back their values and the spirit they created.

“We’re rebuilding that Grovian execution, as we call it, bringing back that heart of Andy Grove, the confidence, the engineering centricity, the discipline, the competitive spirit,” Gelsinger said during a speech at Intel’s annual investor meeting, which was live-streamed on Thursday.

Gelsinger laid out his plans to turn-around the company’s fortunes with a move to manufacturing, while pivoting to fast-growing opportunities like graphics hardware and the automotive industry, while keeping its traditional markets like PCs humming.

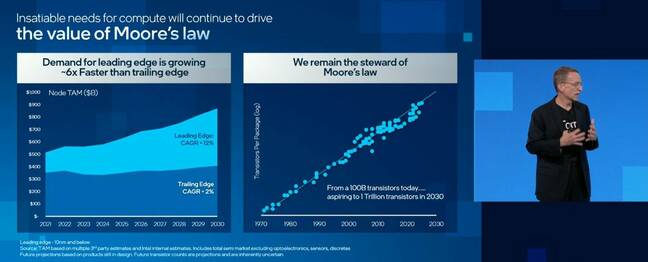

The demand for computing is insatiable with artificial intelligence, electric cars, connected devices, and emerging experiences like the metaverse, Gelsinger said, adding that there will be a bigger demand for general-purpose compute, graphics, accelerators and I/O technologies.

“We estimate that to be a $1 trillion market by 2030 – the doubling of the semiconductor industry over the next decade. And we’re uniquely positioned to capitalize on that,” Gelsinger said.

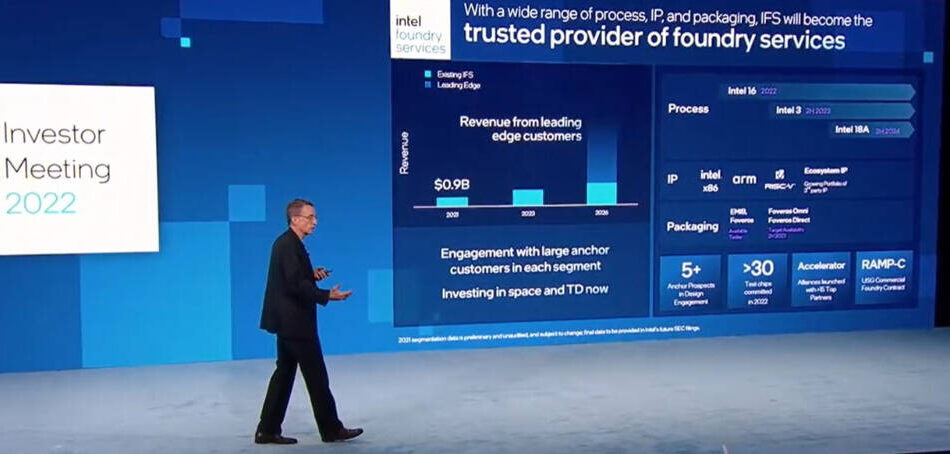

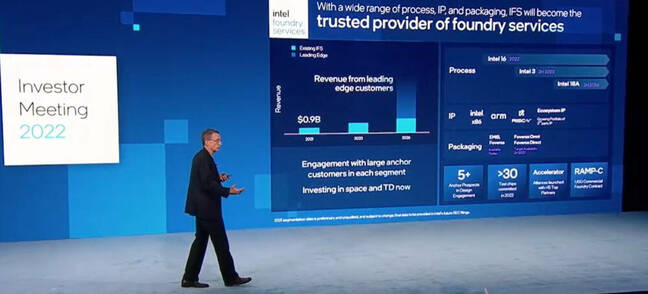

One way to tap into the market is by accelerating a “plan to be one of the largest foundries in the world,” the CEO said. Intel recently announced $20 billion in spending on new fabs near Columbus, Ohio and is expanding operations in other US and Europe factories to meet that demand.

Intel this week also announced it will acquire Israel-based Tower Semiconductor, which has fabs in US, Italy and Japan. Tower is a specialty foundry that makes components for RF, displays and power devices, which are currently in very short supply.

Intel’s goal is to break Asia’s stranglehold on manufacturing. Over the last 30 years, semiconductor manufacturing drifted away from the US and Europe to Asia, which is now making 80 per cent of the chips.

“My moonshot is that by the end of this decade, the US would have gone from 12 per cent to 30 per cent, Europe from 9 per cent to 20 per cent [of manufacturing capacity],” Gelsinger said.

The fab for the world

Intel’s ramping up aggressive manufacturing plans, which includes five new process nodes by 2025. Gelsinger said the company is on or ahead of schedule on all the advanced nodes.

“We said five nodes in four years, and a bunch of you looked and said, Have you gone nuts? Doesn’t it take two years per node? We had confidence … and we remain on or ahead of schedule against the timelines that we laid out,” Gelsinger said.

As if to prove a point, he showed an SRAM wafer from the 18A node, which is slated to start mass production in 2025. Chips made on the 18A will have new transistor technology called RibbonFET and a backside power delivery scheme called PowerVia.

“We’re on a path from 100 billion transistors this year to a trillion transistors on a package by 2030,” Gelsinger said. “As I like to say, until the periodic table is exhausted, we’re not done and we’re going to keep pushing that arc and bending physics to keep Moore’s Law alive and well.”

With that in mind, Intel has set its CPU, GPU and accelerator roadmap to align with its manufacturing roadmap. Intel’s advanced nodes will allow compute tiles to be stacked vertically and linked up through high-speed interconnects.

For one, Intel has accelerated its server roadmap because of the progress on Intel 3 process node tech, which will begin production next year. Intel 3 is an enhancement of the Intel 4, which produces 7nm chips and is the first to use EUV lithography.

The company also unveiled an aggressive GPU roadmap that will see it introduce Battlemage GPUs, which will be integrated as a tile alongside other chiplets containing CPU cores and support circuitry in a single large Meteor Lake processor.

“Meteor Lake is a brand new architecture that will enable tiled GPUs to be integrated on a 3D package. This is super exciting, as this allows us to offer discrete graphics class performance with the efficiency of integrated graphics,” said Raja Kodur, Intel’s graphics boss, in a videotaped speech ahead of Gelsinger’s keynote.

The Meteor Lake chips, which will ship in 2023, will be made on Intel 4 process and deliver a 20 per cent improvement in performance per watt, over its predecessor. Meteor Lake also represents the first time EUV technology will be used for PC chips. Arrow Lake, which will succeed Meteor Lake, will ship in 2024 and be made using the Intel 20A process.

Intel’s current PC flagship is Alder Lake, which will be succeeded by chips code-named Raptor Lake in the second half this year. The chip, made on the Intel 7 process, will have up to 24 cores and 32 threads and be socket-compatible with Alder Lake systems.

The road ahead

The client business has grown rapidly due to unique scenarios like hybrid and remote work, Gelsinger said.

“Looking forward, we don’t expect that kind of growth to continue. Market growth may be low single digits but we see that we have opportunities to grow from other factors as well,” Gelsinger said.

Intel’s revenue in 2021 was $79 billion, and Gelsinger predicted revenue to grow at a rate of 10 to 12 per cent to 2026, with a larger chunk of revenue coming from areas like manufacturing, graphics and accelerated computing.

Intel has had trouble aligning its chip strategy with its manufacturing process. Gelsinger acknowledged the company was lost when he joined as CEO last year following an 11-year break from the company. Gelsinger was previously CEO at software company VMWare.

“When I came back to the company, we were losing talent, and many of you were writing on that – the brain drain,” Gelsinger said.

Many employees who lost confidence are now returning, and Intel is coming back to its roots of being known for a culture of discipline, innovation and execution.

“The band is coming back together and the mojo is back,” Gelsinger said. ®

Source link