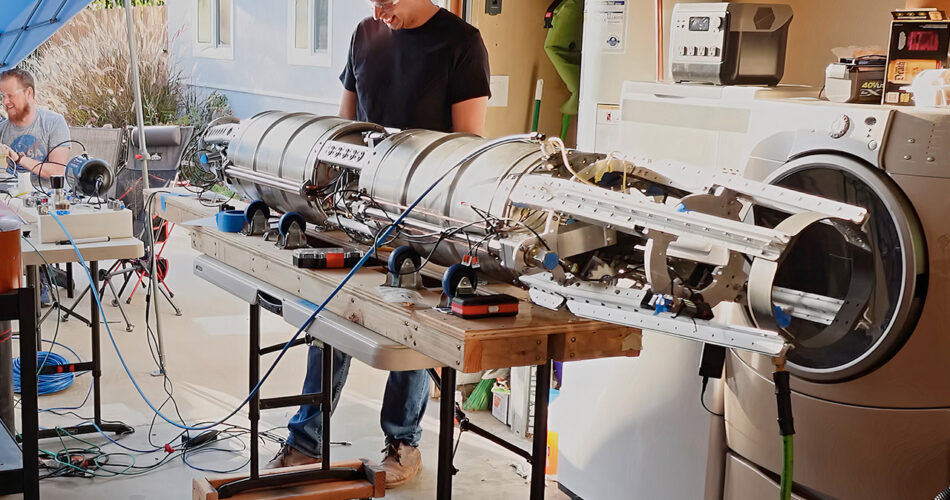

Beer kegs ought to have the ability to preserve carbonation for weeks as a result of strain they maintain. Ryan and his group at Challenge KegRocket checked out one and instantly imagined one thing fully completely different, equivalent to a pair of tanks containing the elements for an precise rocket flight. Early on, the group determined to make use of standard stainless-steel beer kegs as propellant containers as a result of, let’s be trustworthy, they’re a handy start line.

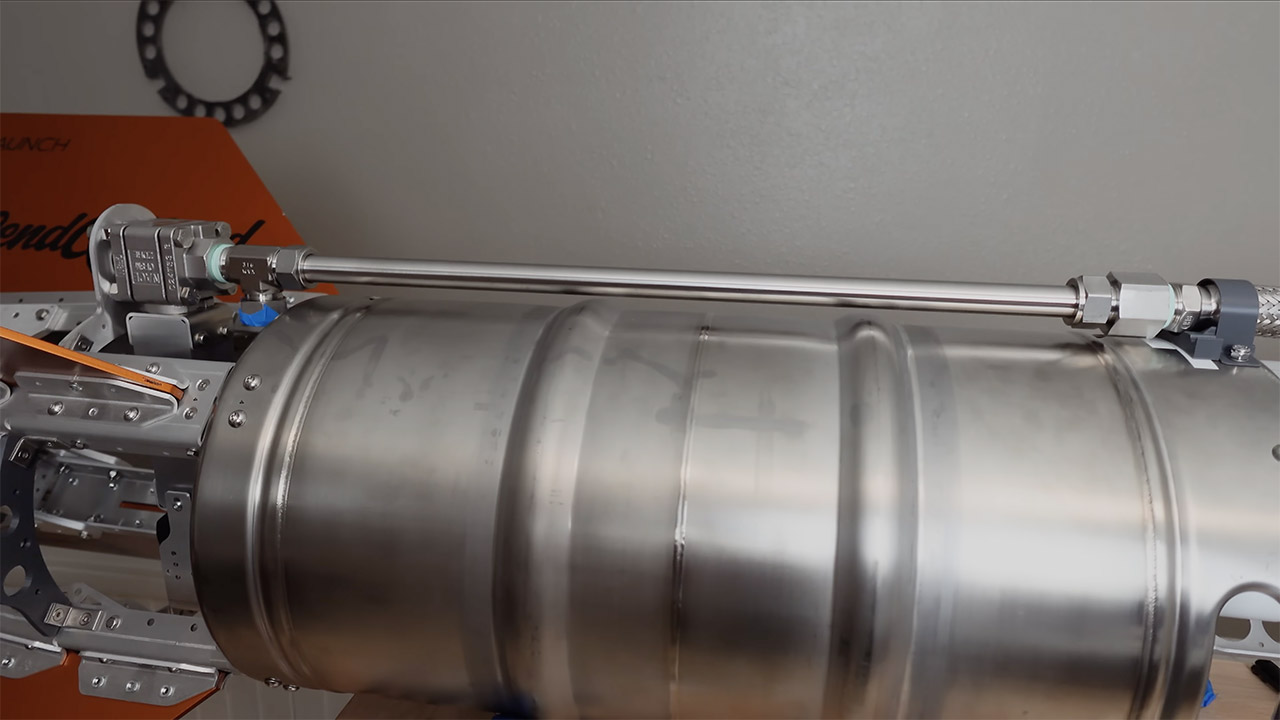

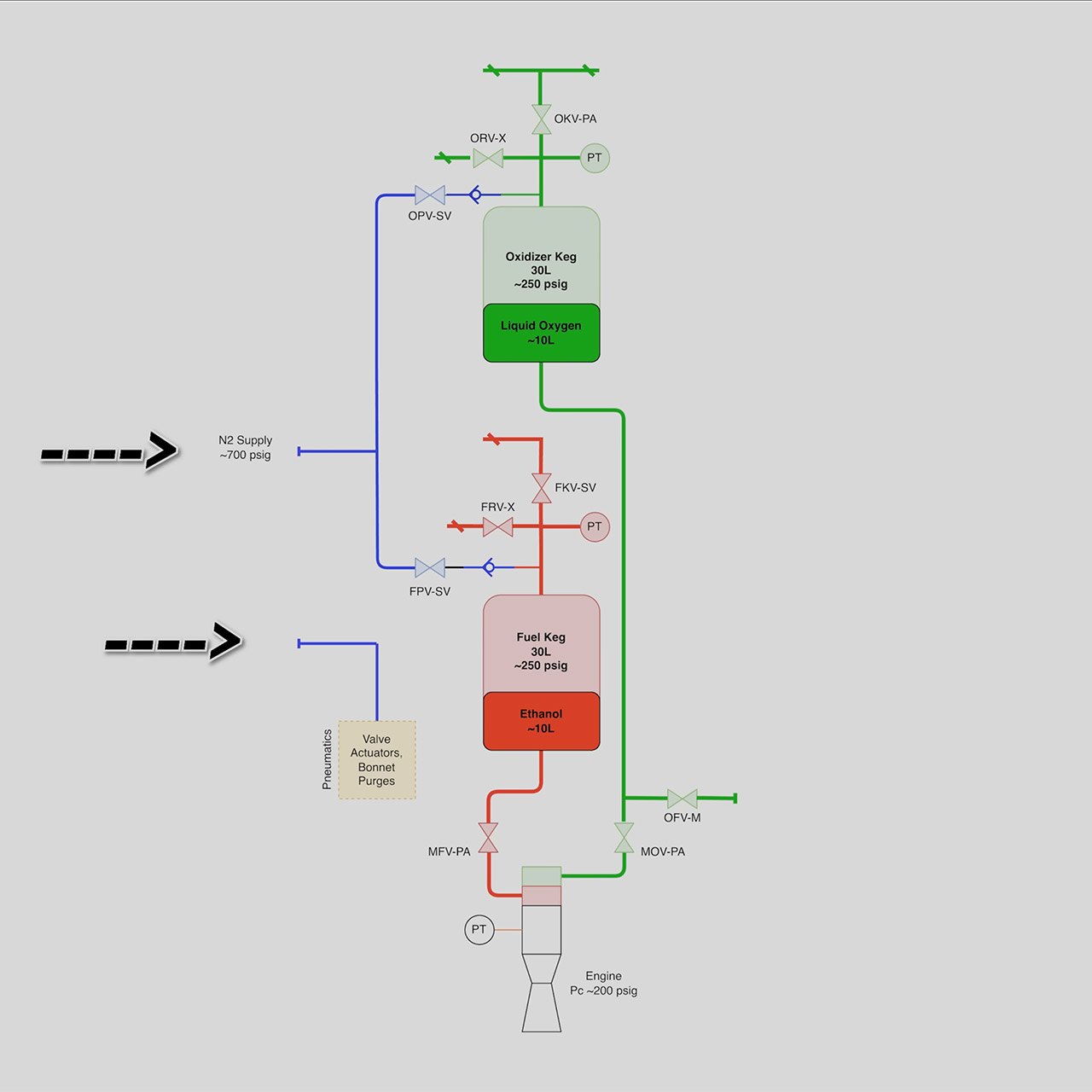

One of many kegs has alcohol as gasoline, all pressurized and able to be pushed into the engine. The second keg comprises liquid oxygen, the oxidizer, chilled to cryogenic temperatures. The entire kegs are pre-built to face up to significantly greater pressures than most of us would ever encounter, and their acquainted form is troublesome to beat. The ridges alongside the edges are additionally versatile sufficient to face up to minor strain and temperature adjustments with out challenge.

LEGO Technic NASA Artemis Space Launch System Rocket Building Toy for Boys & Girls – STEM Learning &…

- BUILD AN OFFICIAL NASA ROCKET – Children put together to discover outer house with the LEGO Technic NASA Artemis House Launch System Rocket (42221) constructing…

- 3-STAGE ROCKET SEPARATION – Younger builders can flip the hand crank to observe the rocket separate in 3 distinct levels: strong rocket boosters, core…

- STEM BUILDING TOY FOR KIDS – This academic rocket package was created in collaboration with NASA and ESA to showcase the genuine system that can…

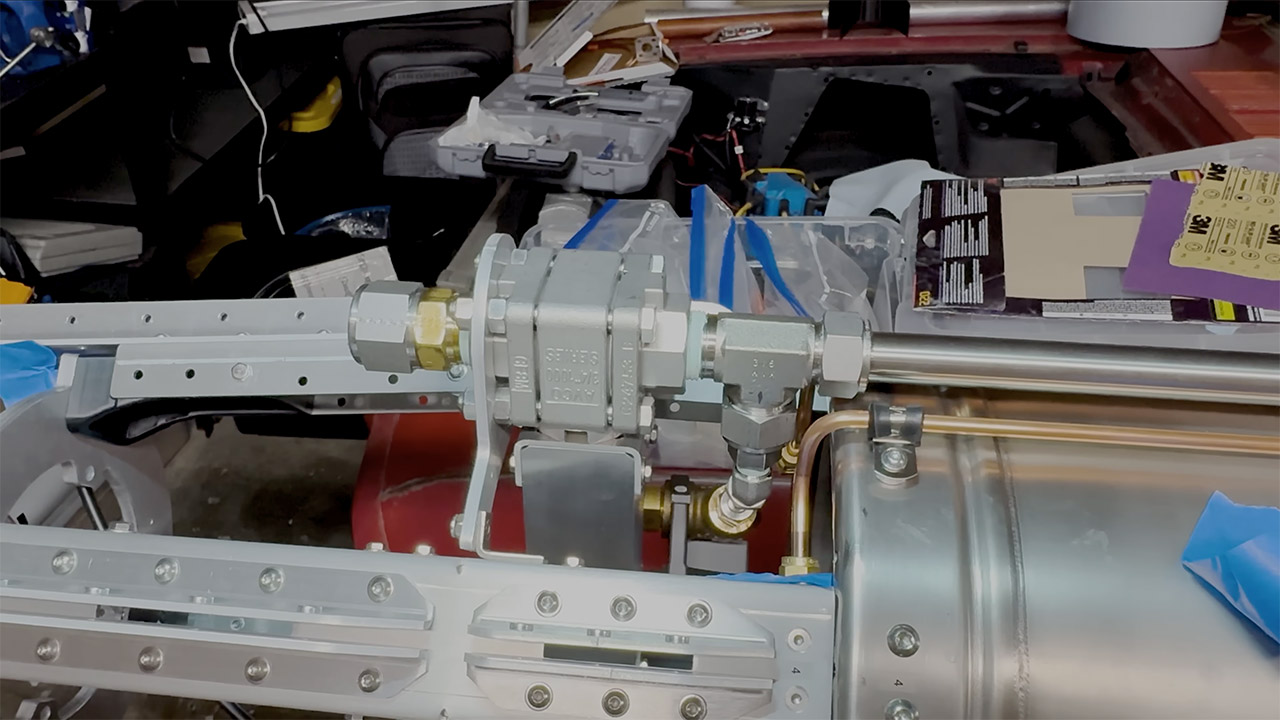

The massive challenge arises when it’s important to plumb all the factor. Liquid oxygen is chilly sufficient to make common seals brittle and nugatory, so rubber O-rings merely fracture when issues get scorching. And, let’s be trustworthy, pure oxygen isn’t supreme for a lot of supplies; they have an inclination to burn or fail. The group used metal-to-metal sealing each time attainable. The plumbing’s spine consists of double ferrule compression fittings, 37-degree flare connections, and exactly chosen NPT threads. The place some flexibility is fascinating, stainless tubing can bend barely because the keg expands beneath strain and the LOX boils out.

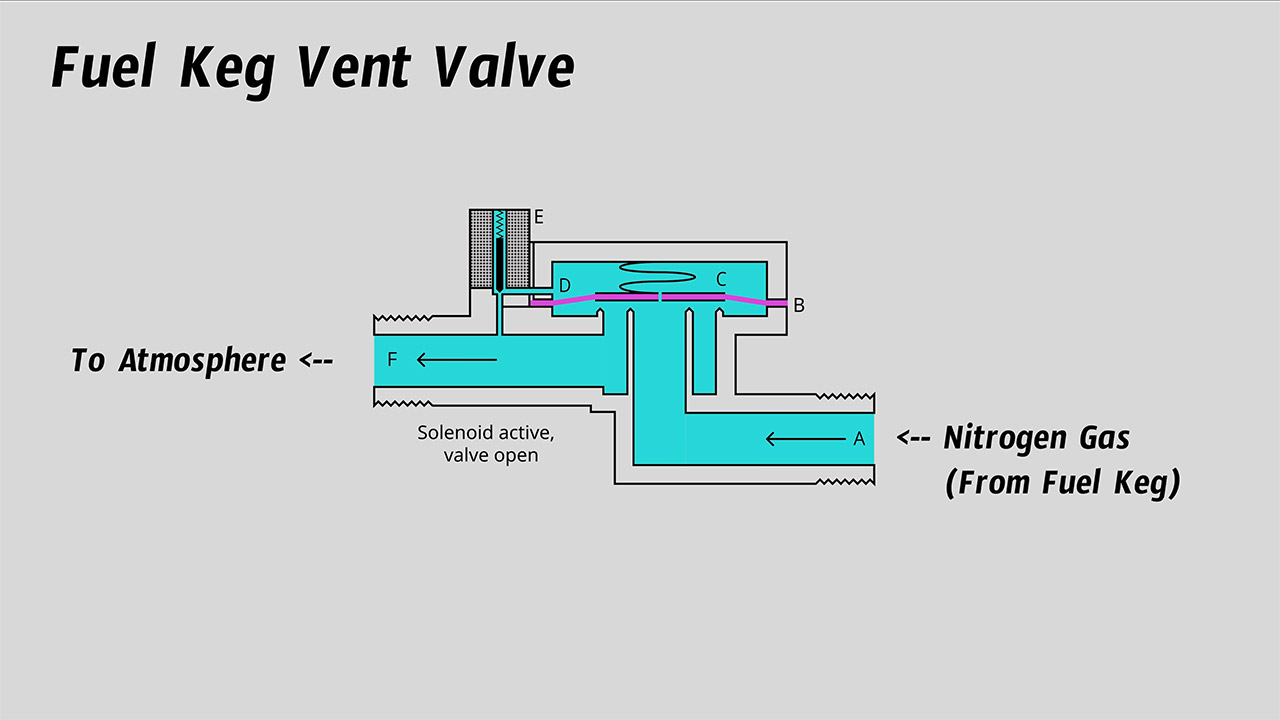

The valves management the move with precision, whereas the principle oxidizer valve is a big industrial ball valve with a pneumatic actuator, a vented ball design to keep away from strain buildup, live-loaded stem seals, and a few fluoropolymer supplies able to dealing with cryogenic temperatures. The gasoline aspect makes use of a normal ball valve from the ironmongery store, nonetheless it does embrace a novel 3D printed bracket. You could have separate valves for filling the oxidizer, venting boil off gasses, and releasing extra strain by way of pop valves. Solenoids handle the pressurization utilizing nitrogen, which is fed by way of umbilicals that detach neatly at launch.

The whole engine is mounted on a bespoke thrust bracket fabricated from metal on a CNC utilizing plans given to JLC. It retains the plumbing neat and is sort of compact. The manifolds are merely carved from aluminum bar inventory and route the propellants to the engine in a tidy, pointed configuration. The LOX keg sits on prime of the gasoline keg, offering some gravity help to get issues began earlier than strain takes management.

Security is clearly on the prime of the checklist, appropriately. The group strain examined all the system with nitrogen, checked for leaks with a cleaning soap resolution, and stuck the one minor one which appeared. To be on the secure aspect, the crew solely goes as much as roughly 70% of the kegs’ ranking limitations, giving them a snug buffer. On the bottom, you simply want two nitrogen traces: one high-pressure one for tank pressurization and one low-pressure one for valve actuators. When the rocket finally lifts off, there’s a useful tear-away connector to maintain the umbilicals neatly organized.

This strategy takes a easy {hardware} design and provides a artistic engineering twist. The kegs function sturdy tanks, making it a viable resolution that didn’t require customized manufacturing. In the meantime, the plumbing system offers with the extreme chilly of cryogenic temperatures in addition to the troublesome process of coping with oxygen that has proven to be as reactive because it has. Earlier episodes on the channel confirmed the undertaking progressing from fundamental idea to setbacks, and naturally the same old suspects, integrating the avionics with the assistance of some companions, and finishing up smaller-scale testing equivalent to a liquid motor up in an airframe.

The fluid system has simply accomplished its strain and leak checks, and if issues proceed as deliberate, a static hearth would be the subsequent essential step, adopted by the total launch that the crew has been aiming for because the starting.

[Source]

Source link