Yearly, thousands and thousands of passengers board a Boeing 777 and settle into their seats because the airplane gently climbs to cruising altitude. Even essentially the most skilled flyers are unlikely to think about the tiny little field of electronics and sensors that work tirelessly to make the air contained in the airplane protected to breathe.

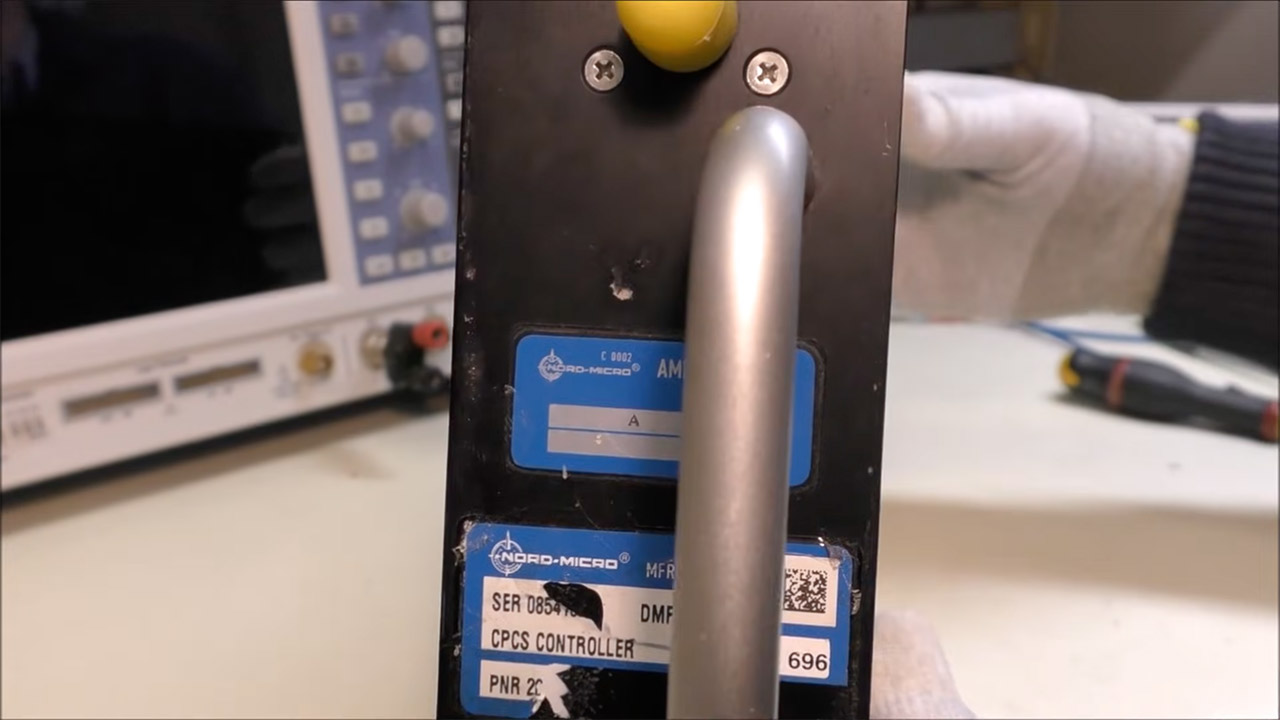

This gear, referred to as the Cabin Stress Management System controller, is the workhorse that maintains the correct strain contained in the airplane fuselage. We get a superb peek inside one among these machines courtesy to a teardown by an aviation fanatic named Michel, who demonstrates how the whole system works.

LEGO Icons Shuttle Carrier Aircraft Building Set for Adults – Spaceship & Airplane Model Kit for Adults,…

- 2 AVIATION LEGENDS, 1 BUILD – Recreate the long-lasting Boeing 747 and NASA House Shuttle Enterprise with the LEGO Icons Shuttle Provider Plane (10360)…

- DEPLOY LANDING GEAR – Flip the dial to increase the large 18-wheel touchdown system in your airplane mannequin, identical to actual flight operations

- AUTHENTIC FEATURES & DETAILS – Take away the tail cone, engines, and touchdown gear from the NASA shuttle and stow them within the cargo bay throughout flight

Air enters the cabin via engine bleed methods as sizzling, pressurized air. It’s then cooled and conditioned by air packs earlier than being provided overhead to passengers. Nevertheless, in an effort to keep a relentless air strain inside the airplane, among the air have to be launched, which is the place the big outflow valves are available, one within the entrance and one within the again. The vast majority of the air will depart via the again valve, which is simpler in sustaining air circulation.

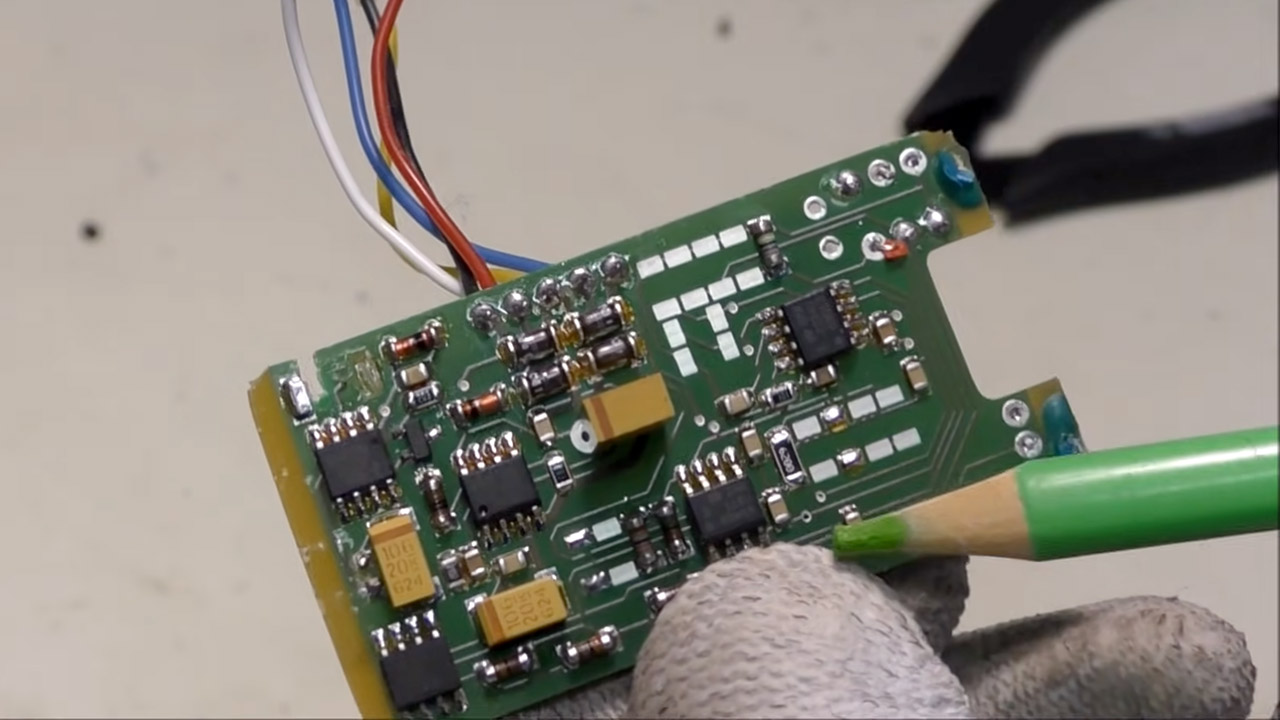

The controller operates the valves, making microscopic changes to take care of the best air strain. Each 777 consists of two backup methods, one among which is the controller. That’s as a result of if one system fails, the opposite will take over, protecting the air protected to breathe at excessive altitude. While you open the sturdy steel container and peek inside, you’ll discover how dense the circuit boards are, and the way they’re all protected against moisture and vibration by a novel coating. Moreover, the entire connectors are secured to forestall them from vibrating unfastened.

On the coronary heart of all of it are two small strain transducers manufactured by Nord-Micro. These are the gadgets that detect cabin air strain using a classy expertise referred to as piezoresistive. It operates by utilizing microscopic silicon parts that adjust their resistance to electrical energy because the strain on them varies.

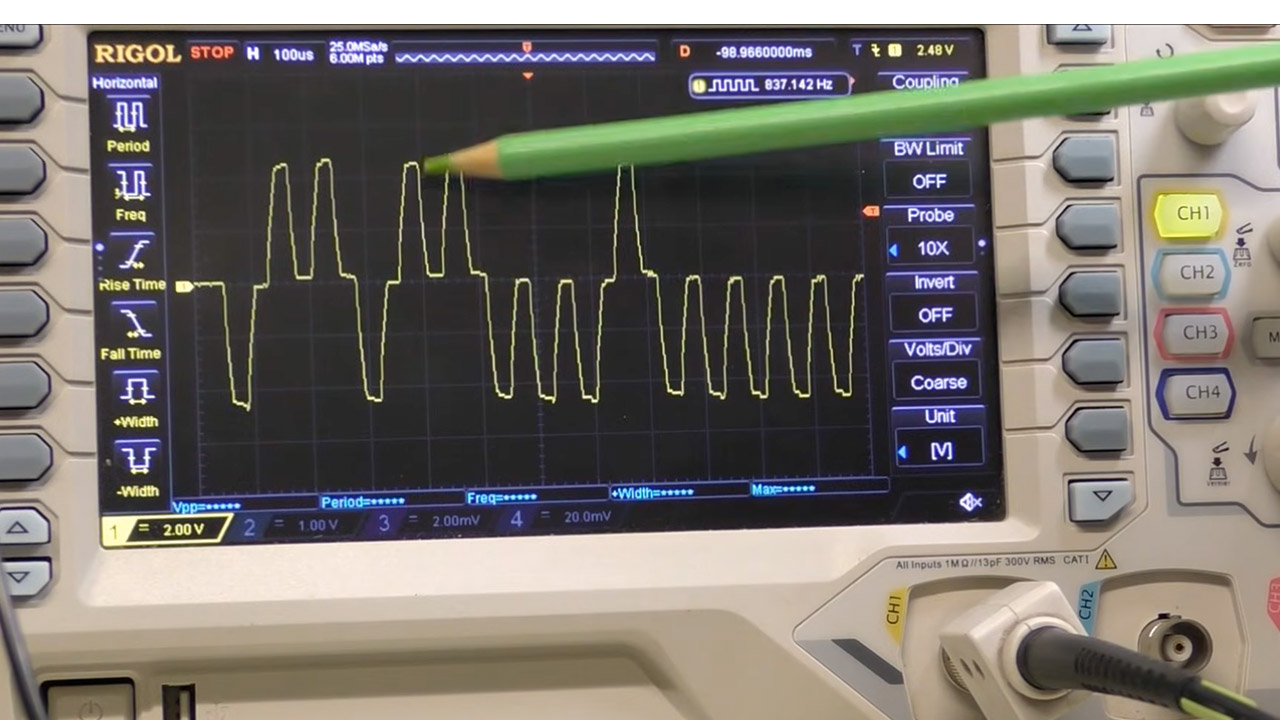

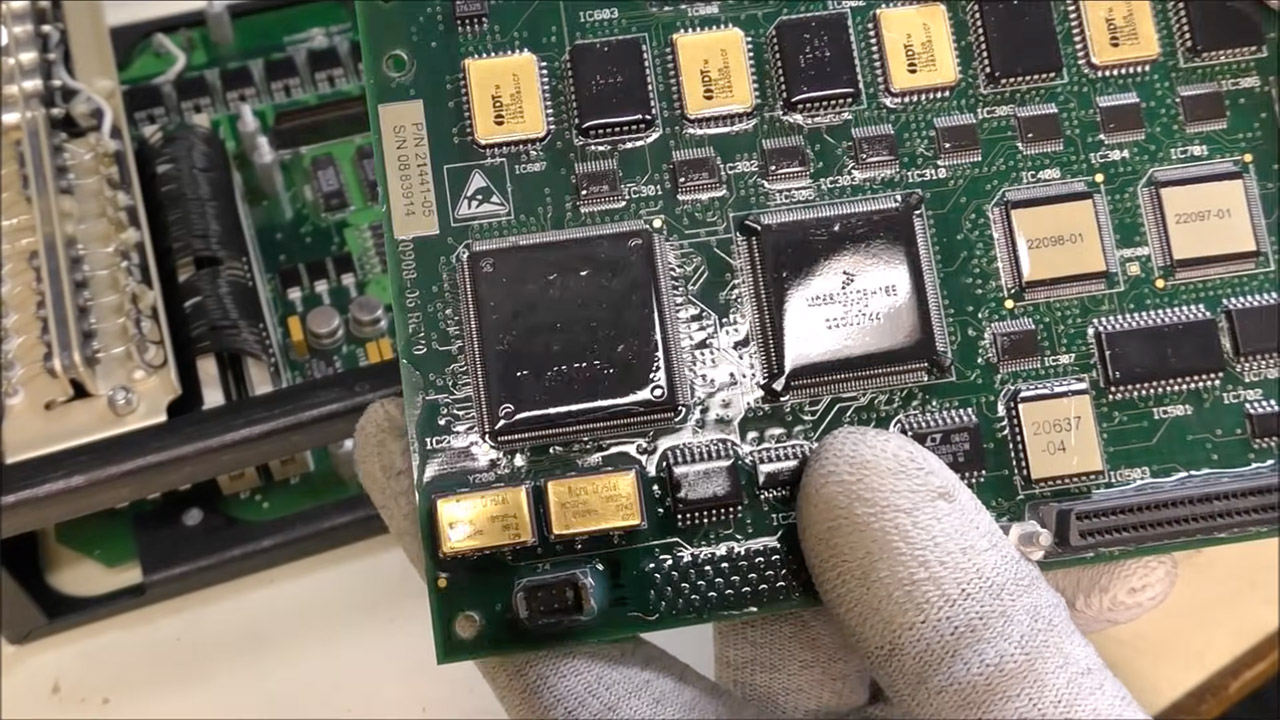

Certainly one of these transducers performs the first perform, whereas the opposite serves as a backup. What happens is that each ship indicators to a number of analog-to-digital converters, which convert the strain readings into digital knowledge that may subsequently be dealt with by these super-fast programmable gadgets referred to as FPGAs. These chips are extraordinarily quick and reliable at performing the logical duties required by the pc.

An ARINC 429 transceiver handles all communication between the controller and the remainder of the airplane’s gear, delivering and receiving data akin to altitude in addition to vacation spot elevation. It’s all managed by software program, which employs a extremely specialised algorithm to exactly modify the valve areas. The best way it really works is that when the airplane ascends to larger altitudes, the strain inside the cabin steadily decreases, at not more than 200 ft per minute equal. When the airplane descends, the method reverses and the strain steadily rises once more. When the airplane lands, the valves totally open, permitting recent air to enter.

One of the crucial good options is that the valves themselves have redundancy in-built, so even when one fails, the opposite can maintain the strain as much as a protected degree. There are additionally security mechanisms that maintain the air strain from rising too excessive, which may put pressure on the plane. Pneumatic actuators function the valves by blowing air into them, very similar to a little bit balloon contained in the valve, to stability the inner and exterior air pressures.

Each element on this system is designed to face up to the pains of flight, together with years of warmth, chilly, and turbulence, with out ever failing. The event course of was way more stringent than traditional, with every line of code being scrutinized to make sure that it met the important requirements. There are even watchdog timers that carry out a reset if the system ever turns into caught.

[Source]

Source link